PUZ-ZM R32

Our Eco-conscious Power Inverter Series is designed to achieve industry-leading seasonal chergy-efficiency throught use of New R32 refrigerant and advanced technologies.

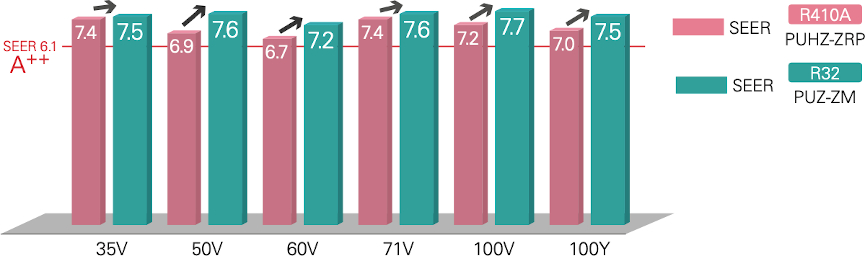

Industry-leading energy efficiency

Introduction of new R32 refrigerant realises improved cooling efficiency. Rating of more than 7.0 achieved for all capacity range.

Introduction of new R32 refrigerant reduces energy consumption and re- alises energy savings.

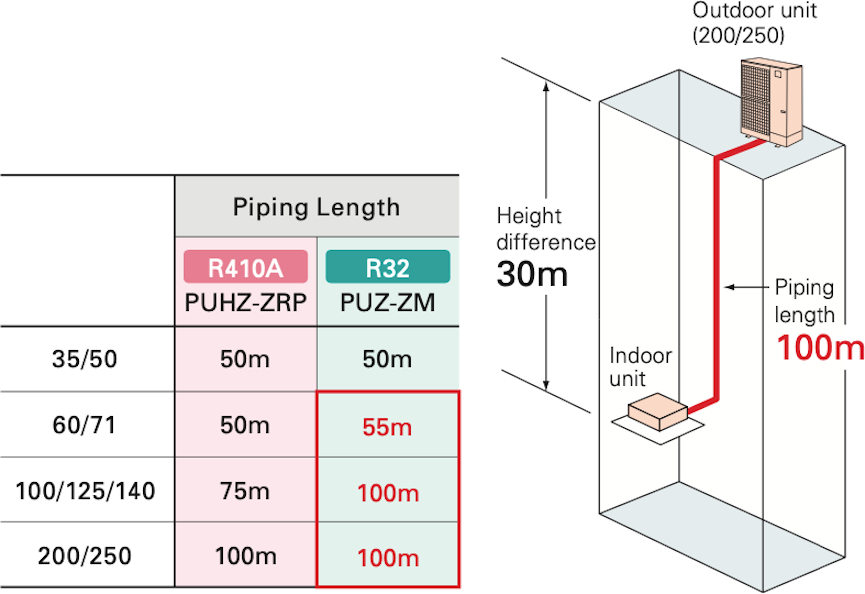

Longer piping (60/71/100/125/140/200/250)

Longer piping length realised for 60, 71, 100, 125, 140, 200 and 250 classes, widely increasing installa- tion flexibility.

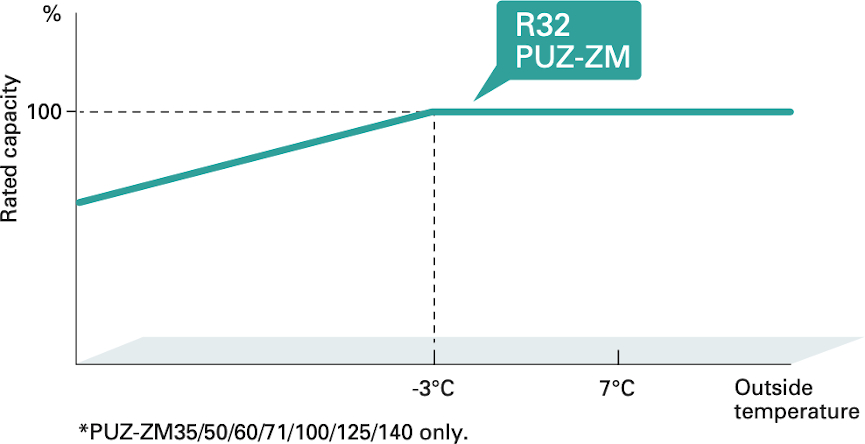

Rated heating capacity maintained down to –3°C*

Rated heating capacity maintained even when the outside temperature is down to –3°C. Stay warm even at times of cold weather.

2+1 Back-up rotation*

The use of a three-refrigerant air conditioning system enables you to utilize the back-up, rotation, and cut-in functions. This allows you to implement effective risk management for added peace of mind.

*Availability of this function is depending on outdoor unit, indoor unit and remote controller.

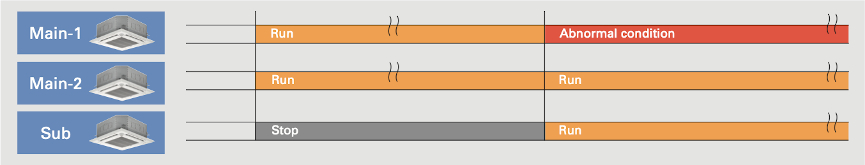

Back-up Function

In the unlikely event that one of the units stops operation due to an abnormality, the standby unit immediately starts back-up operation. Being fully prepared for a failure guarantees that and operation is always available and gives you the confidence that your system will be reliable in any situation.

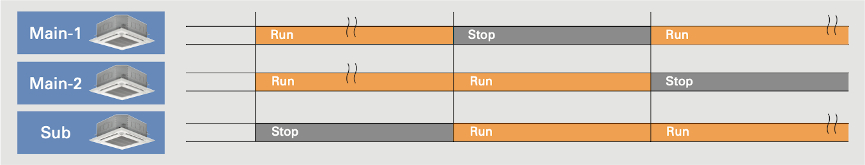

Rotation Function

A single remote controller is used to operate three-refrigerant air conditioning system in a rotation pattern. Reducing the burden on the equipment allows you to maintain a longer time between maintenance and increases product life.

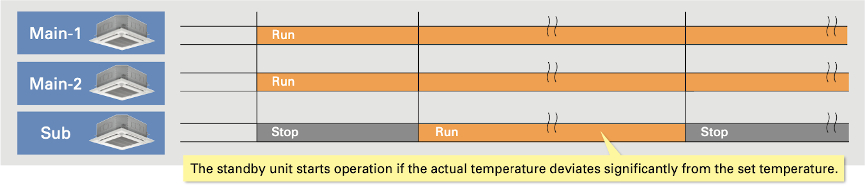

Cut-in Function

If the actual room temperature greatly differs from the set temperature and two-refrigerant air conditioning system is insufficient, the standby unit starts operation to provide support.

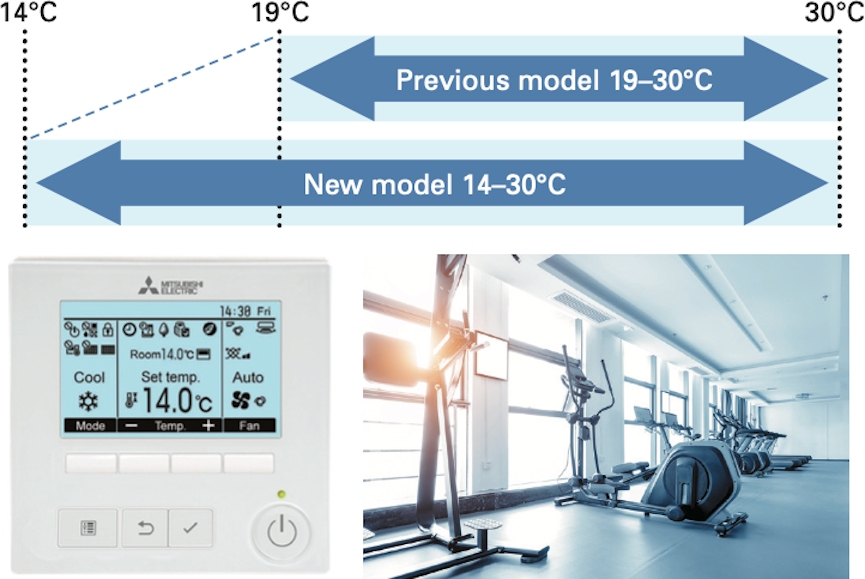

Extended cooling set temperature range*

In environments such as gyms where people do strenuous exercise, even if the room is cooled to an appropriate temperature, people may feel that it is hot, and they need a cooler air. To satisfy such demands, we have extended the lower limit of the cooling set temperature range from 19–30°C. to 14–30°C.

*Insulation kit (PAC-SK36HK-E) is required when indoor unit is PLA series.

*Availability of this function is depending on outdoor unit, indoor unit and remote controller.

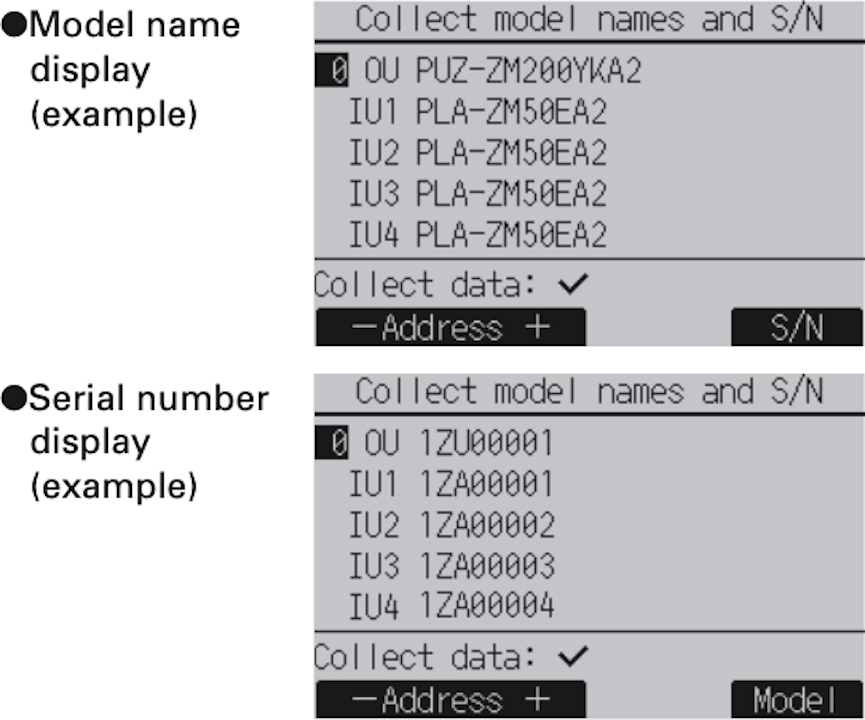

Display of model names and serial numbers*

The model names and serial numbers of the indoor/outdoor units that are connected to the MA smart remote controller can be automatically acquired and displayed through one simple operation. This eliminates the need to directly check each unit and helps with inquiries in the case of an abnormality.

*Availability of this function is depending on outdoor unit, indoor unit and remote controller.

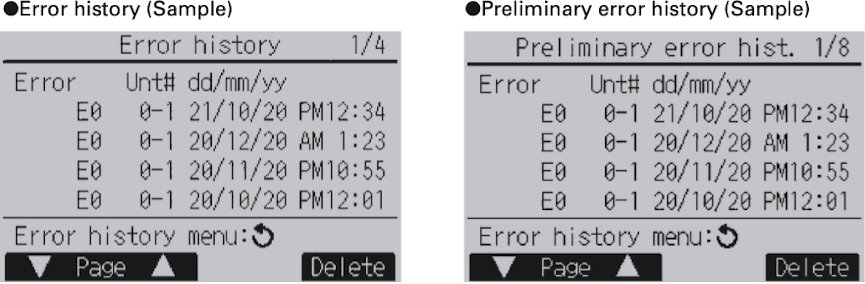

Preliminary error history*

In addition to error history, the history of preliminary abnormalities can be displayed. The feature enables the unit status check during inspection and maintenance.

*Availability of this function is depending on outdoor unit, indoor unit and remote controller.

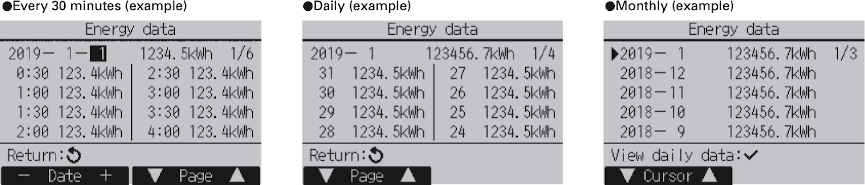

Display of power consumption*

It is possible to measure, acquire, and display the amount of energy used by each air conditioning system.

< Data Collection Period >

Time data: Every 30 minutes over the past month Monthly/daily data: Monthly over the past 14 months

Energy consumption values are calculated from estimated power consumption values according to the operating conditions. They may vary from the actual power consumption values. Please note that the power consumption of optional parts is not included except in the case of optional parts that have their power supplied directly by the outdoor unit.

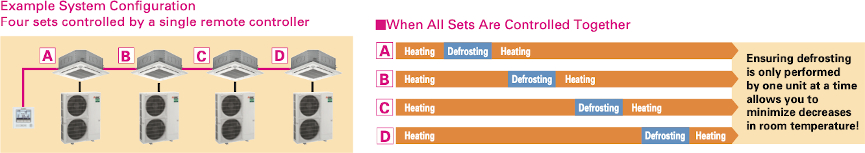

Improved defrosting performance*

*Availability of this function is depending on outdoor unit, indoor unit and remote controller.

Avoiding Simultaneous Defrosting

When each of multiple units is in operation for heating in the same space, these may start defrosting at the same time, resulting in a drop in the room temperature. Therefore, we have developed a new function that controls up to four-refrigerant air conditioning system to avoid simultaneous defrosting. By ensuring that defrosting is only performed by one unit at a time, it is possible to minimize any decrease in room temperature.

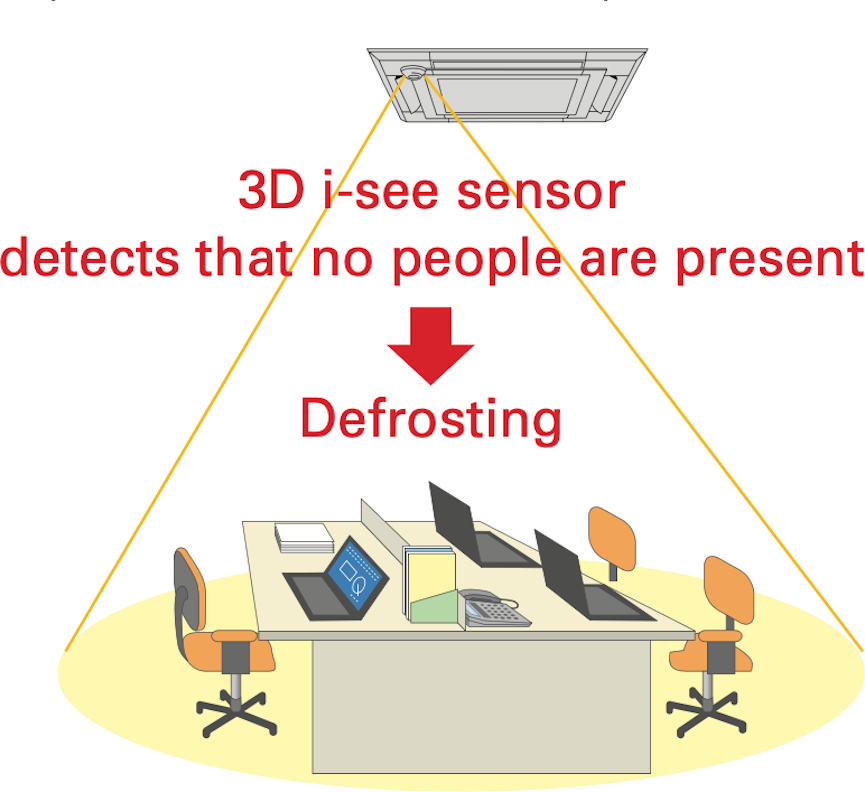

Defrosting When People Are Absent

The use of the 3D i-see sensor allows a more comfortable defrosting schedule. After a large amount of frost has built up, the system will switch to defrosting when the 3D i-see sensor detects that no people are present. By minimizing defrosting while people are in the room, there is a much lower chance of a temperature drop while the room is occupied.

* Only compatible with 4-way cassette and 2x2 cassette models with an attached 3D i-see sensor panel. Even though people are present in the room, the defrosting process may start if all defrosting conditions are met.

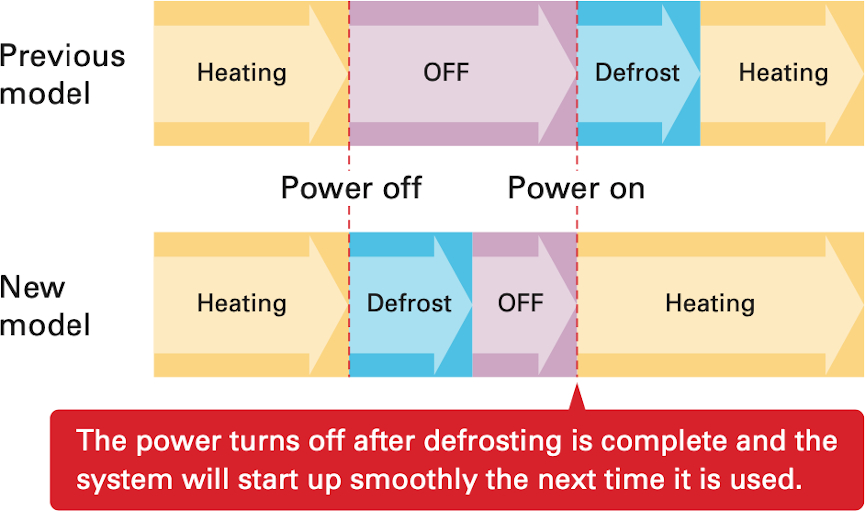

Defrosting When Operation is Stopped

It takes a long time to start operation if there is an excess build-up of frost. Therefore, each unit is equipped with a control system where defrosting is performed immediately after operation is stopped when there is a large amount of frost. This allows heating to be quickly started the next day.

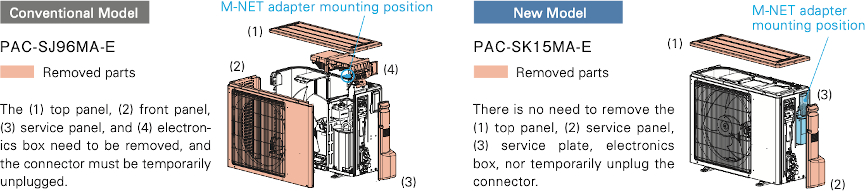

Easier M-NET Adapter Installation

The optional M-NET adapter, which allows centralized control (M-NET control), is now easier to install. The redesigned mounting position significantly reduces the time and effort for installation.

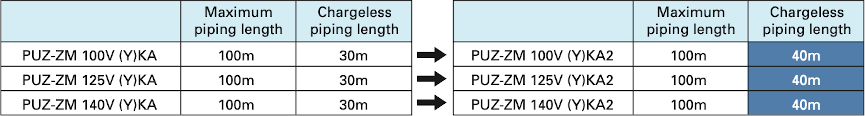

Improved chargeless piping length ZM100/125/140

PUZ-ZM100/125/140V(Y)KA used to have a chargeless pipe length of 30 m. However, starting with the V(Y)KA2 model, this has been ex- tended to 40 m. This allows it to be used for a wider range of applications without the need for additional charging of refrigerant.

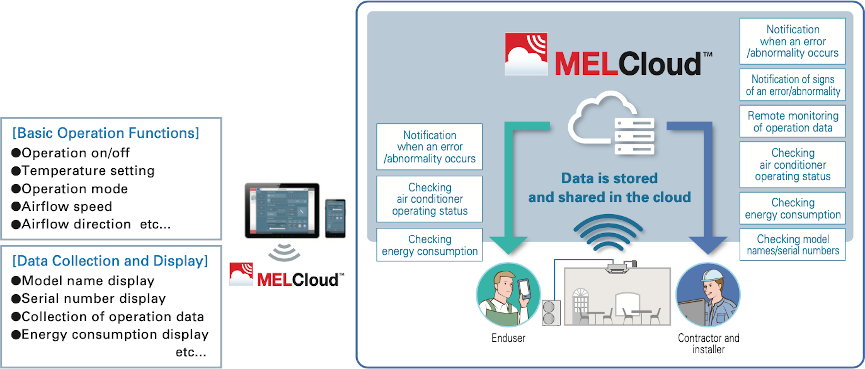

Utilizing IoT for Improved Convenience*

*Availability of IoT functions are depending on MELCloud version.

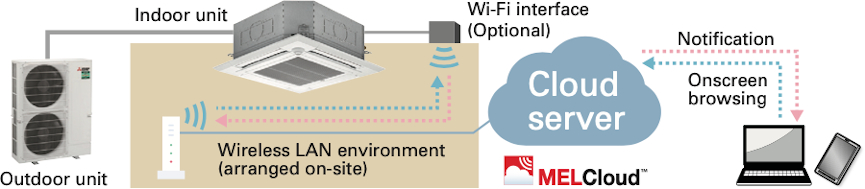

By connecting to a MAC-587IF-E Wi-Fi interface, it is possible to collect data and perform air conditioning control via MELCloud. In addition to basic functions such as turning the power on/off and setting the temperature, it is also possible to acquire data used for maintenance and inspection such as model names, serial numbers, and operation data.

MELCloud System Configuration

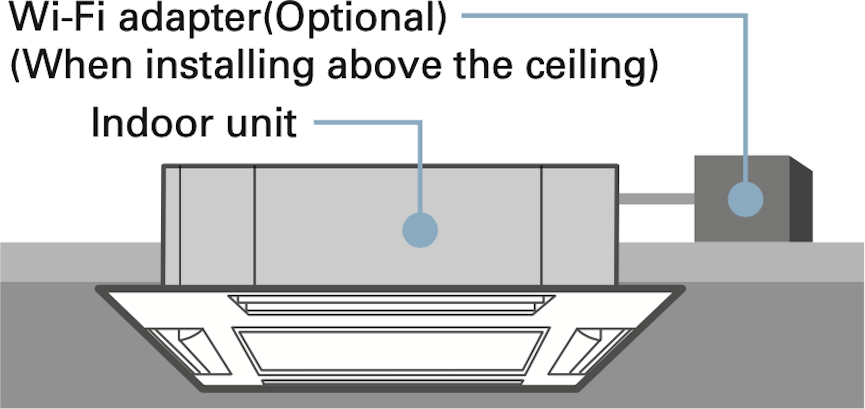

Wi-Fi Adapter (Optional) Installation

On-Site Installation and Configuration

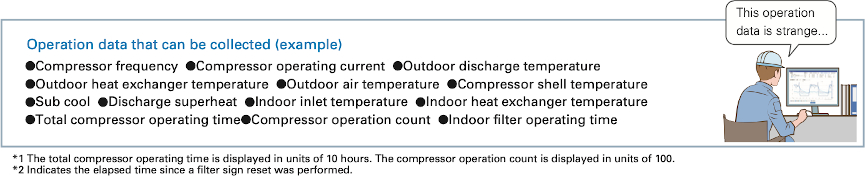

Collection of operation data

All the operation data required for maintenance and inspection can be collected in a simple step. This data can then be easily checked via MELcloud. This makes it easy to check the operating status data even in cases when it is difficult to do a visual inspection. This allows you to quickly identify any system malfunctions. This function also helps to improve the quality of installation work and shortening the time required for maintenance and inspection.

Demand control

It is possible to control air-conditioners to appropriately operate according to the energy supply-demand adjustment by electric power companies and each electricity rate plan of end users.

e.g.

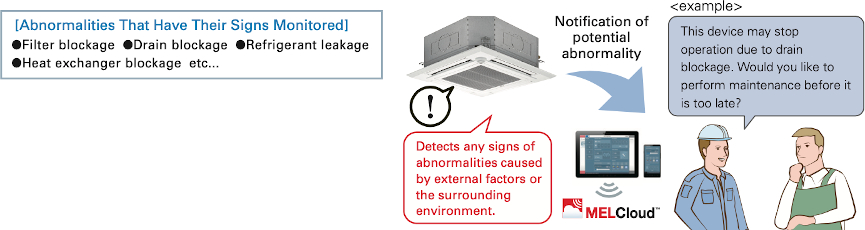

Notification of potential abnormality

The comprehensive analysis of operating data allows the early detection of abnormalities in small functional parts by alerting the operator of any signs of abnormal behaviour. The recognition in advance of abnormalities in each unit further improves the ease of servicing and maintenance. Since this allows a countermeasure to be implemented before the abnormality requires the unit to be completely shut down, it is an effective method for maintaining the unit in its optimum condition.