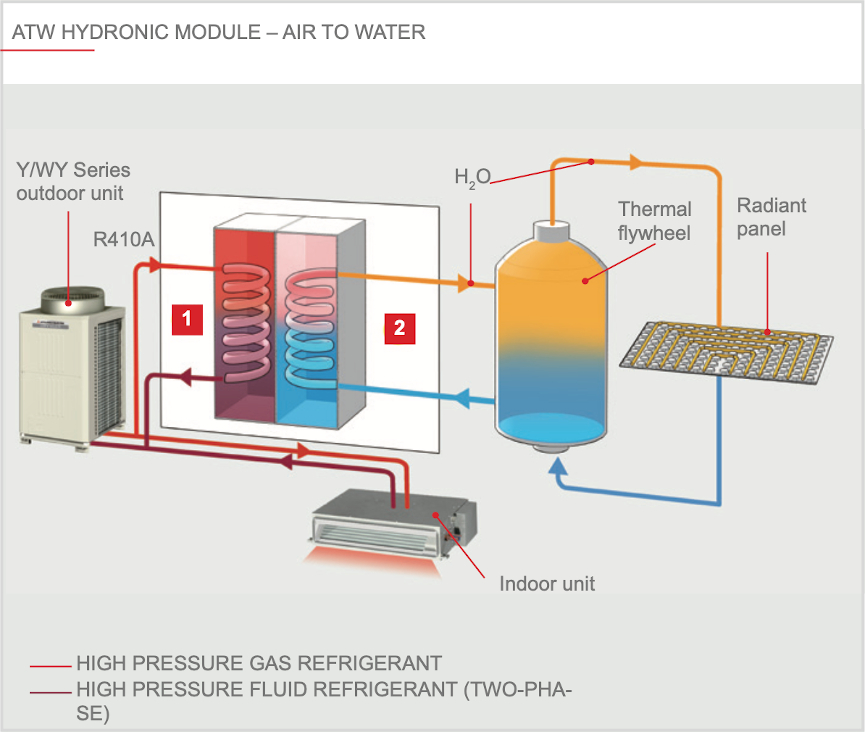

ATW hydronic module – Air to water

Mitsubishi Electric has developed the ATW reversible air-water heat pump hydronic module specifically for hydronic heating and air conditioning systems. The refrigeration side of the module may be connected to VRF CITY MULTI SMALL Y and Y Series outdoor heat pump units, or to R2 heat recovery units. The hydronic side of the module may feed heated underfloor systems or other similar utilities, to provide heating in winter in heat pump mode, or cooling in summer in conditioning mode.

Connecting these modules to R2 Series VRF CITY MULTI heat recovery outdoor units offers extraordinarily levels of efficiency, especially in spring and autumn, with extremely high COP values. The HWS hydronic module can produce hot water at temperatures up to 40°C in the return line (45°C in delivery line), with a heating capacity of up to 12.5 kW per module which, however, is scalable in relation to internal demand.

Hybrid systems

Like the HWS module, the ATW hydronic module may be used to create hybrid systems, with both hydronic modules and VRF direct expansion units. For instance, this makes it possible to create a system that can heat certain rooms with radiant panels (a heating solution that is now very popular, as it offers uniform temperatures and quietness) and heat other rooms using appropriate Mitsubishi Electric indoor units (cassette units, wall-mounted units, ducted units etc.). Similarly, conditioning in summer may be performed with a heated underfloor system in rooms where this is installed, and with cooled air in other rooms, via standard VRF indoor units.

This makes it possible to use the most effective treatment solution possible for each interior space, catering for both the requisites of the specific application and the preferences of the user. As well as superior energy efficiency, a hybrid system also offers the extraordinary flexibility needed to cater for very diverse situations, which a conventional conditioning system simply does not.

Main features

The functional characteristics of the ATW hydronic module cater for the needs of a very wide variety of different installations:

- nominal heating capacity: 12.5 kW;

- nominal cooling capacity: 11.2 kW;

- outdoor operating temperature range, heating mode: -20°C to +32°C (R2 heat recovery series); -20 to +15.5°C (Y heat pump series);

- outdoor operating temperature range, conditioning mode: -5°C to +46°C (R2 and Y series);

- return hot water temperature range: 10°C to 40°C;

- mains power: single-phase, 230V AC;

- individual thermal energy consumption billing with field devices.

Operating principle

The ATW reversible heat pump hydronic module consists essentially of a brazed plate stainless steel refrigerant-water heat exchanger connected to the VRF CITY MULTI outdoor unit on the refrigeration side, and to the hydronic circuit of the system (radiant panels, radiator units etc.) on the water side. The module is equipped with an electronic expansion valve which modulates the flow of refrigerant in the heat exchanger in response to heating or cooling demand and the demand required by the electronic management and control circuit. The entire system is encased in a housing with compact dimensions and very limited weight comparable to a wall-mounted boiler. The high COP value attained by the ATW hydronic module means that it delivers superior comfort with minimal operating costs, contributing to reducing the CO2 emissions produced for energy production at the power plant. This offers a two- sided advantage as emissions are not only reduced, but also delocalised away from populated areas.

Control and adjustment system

Like the HWS module, the ATW hydronic module is equipped with a sophisticated control system offering a wide choice of functions, selectable in relation to the needs of the installation and the preferences of the user.

The ATW module may be associated with its own independent remote controller (PAR-W21MAA), allowing the user to configure all operating settings, including water temperature, which may be displayed either for the delivery circuit or for the return circuit.

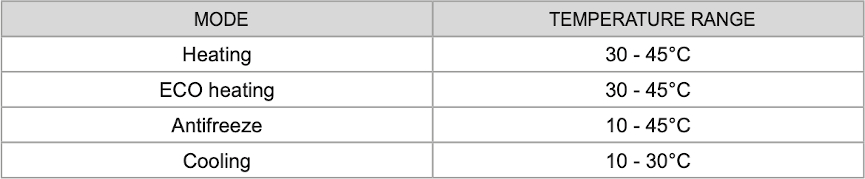

The water temperature reading displayed depends on the type of installation and on the auxiliary controller devices used. The return circuit reading configuration is the most widely used of the two, and allows precise control over the water temperature in the inertial accumulator tank (which is recommended) as a means to balance flows. Once the set temperature is reached, the ATW continues to operate to maintain a constant value.

Note that with this configuration, the delivery temperature is normally higher (max. 45°C) than the set temperature until the set temperature itself is reached.

In installations operating in summer, the ATW produces cold water at a temperature regulated with the same method, based on the primary delivery circuit reading or the return circuit reading.

As the cooling action of the radiant panels only reduces the sensible heat of the interior space, suitable dehumidification systems may also be included in the installation.

The ATW hydronic module can be configured for the following operating modes and hot water temperatures:

Documentation

General Catalog

Comfort & IT Cooling Systems - Full product catalogue 2024

Download