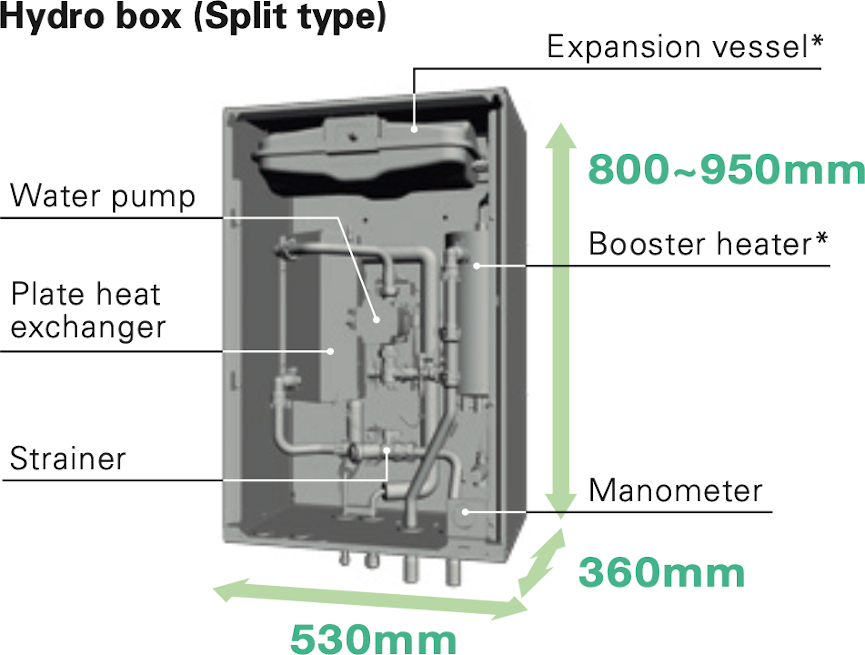

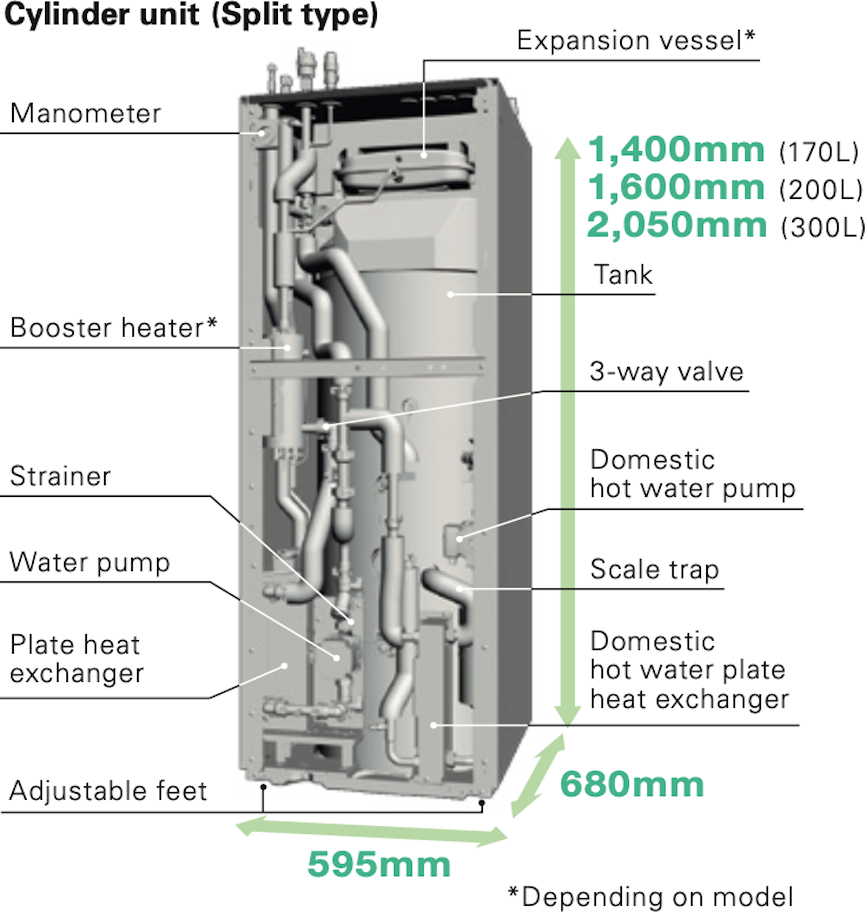

All-in-one Compact Indoor Unit

- All-in-one: Key functional components are incorporated

- Compact cylinder unit: 1,400~2,050mm in height

- Compact hydro box: Only 530×360mm footprint

- Easy installation: Factory fitted pressure relief valve

- Easy service: Relevant parts are located at the front of the unit for easy maintenance

- Easy transport: Handles attached on front and back (cylinder unit)

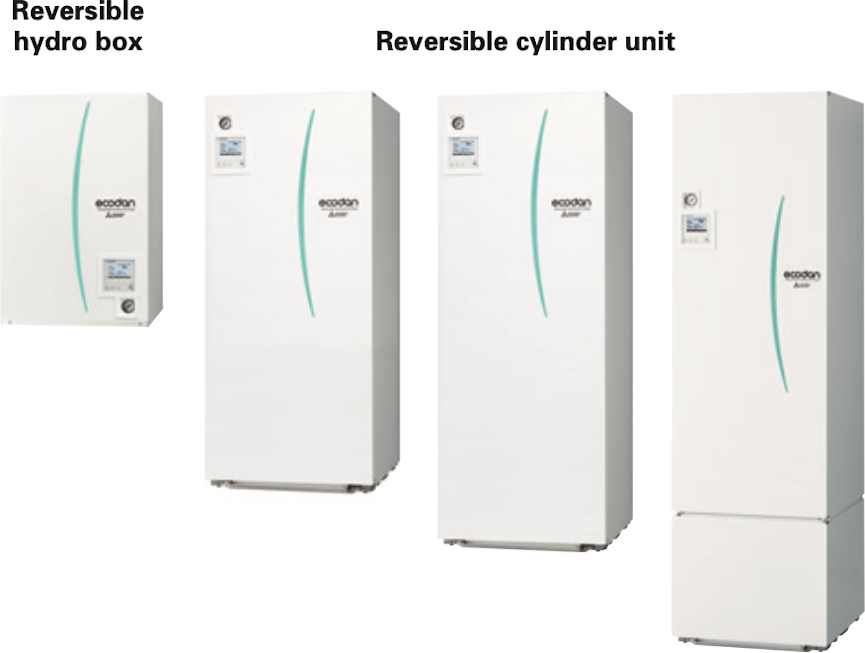

Line-up

Ecodan’s line-up has many types of indoor units to satisfy diverse customers’ needs, requests and local regulations.

It includes various capacity units, with/without booster heater, with/ without an expansion vessel, etc. In addition, a reversible hydro box and a reversible cylinder unit are available.

Available options

- Packaged or Split type

- With/without booster heater

- With/without expansion vessel

- Cylinder unit has an integrated 170L/200L/300L stainless steel tank

- Hydro box is control ready for domestic hot water with a stand-alone tank (locally supplied)

Reversible Models

Perfect Comfort in Winter and Summer Time, Thanks to Our Reversible Models.

Reversible models are now available for both hydro box and cylinder units (Both for split type and cylinder unit for packaged type).

The new reversible cylinder is now able to produce cold water for cooling use and can alternatively produce domestic hot water in summer time.

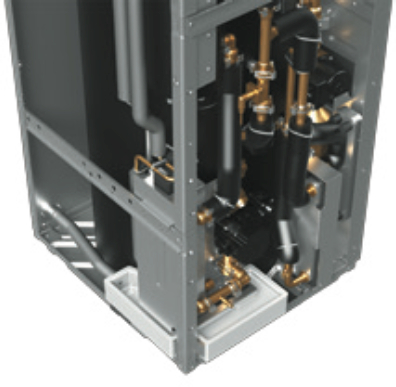

Simple Piping Arrangement

All water piping is aligned at the rear side of the unit for easy connection and neat finish.

Easy Adjustment

Adjust bolt capable of 50mm expansion for easy installation on uneven surfaces.

Built-in Drain Pan for Reversible Cylinder Models

Reversible models now include a built-in space saving drain pan and the drain socket is positioned at the back of the unit. With use of the adjuster bolt, the outlet height can be higher than 50mm, allowing 5m drainage.

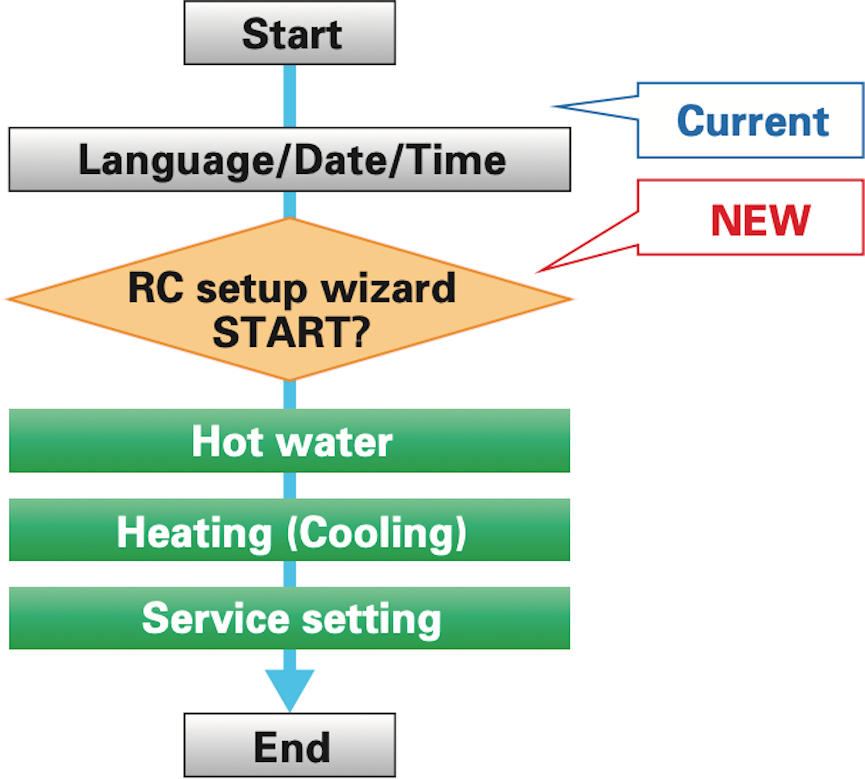

Initial Setting Wizard

In addition to language, date and time, you can set up hot water and heating/cooling operation, pump speed, flow rate range initial setting much simpler than previous models.

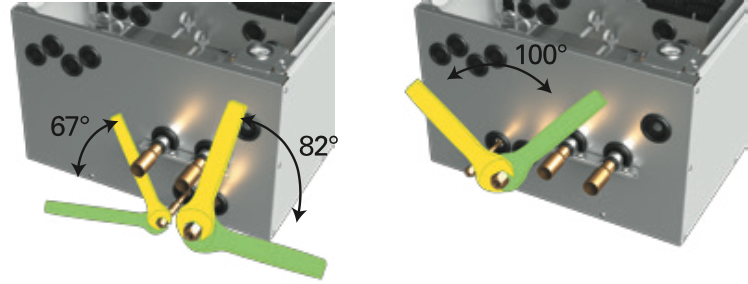

Hydro Box Piping Arrangement Improvement

Through structural innovation related to the space around the pipes, the area where the spanner can be moved has been increased, thus improving pipe work and enabling it to be completed smoothly.

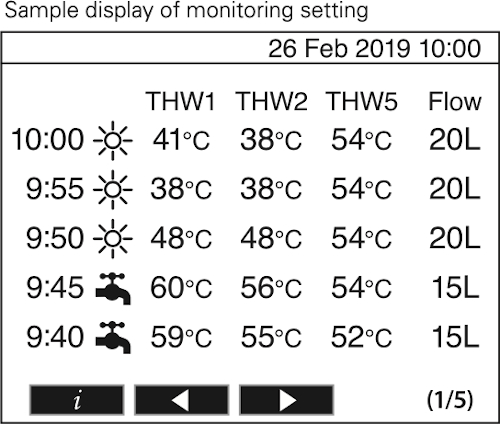

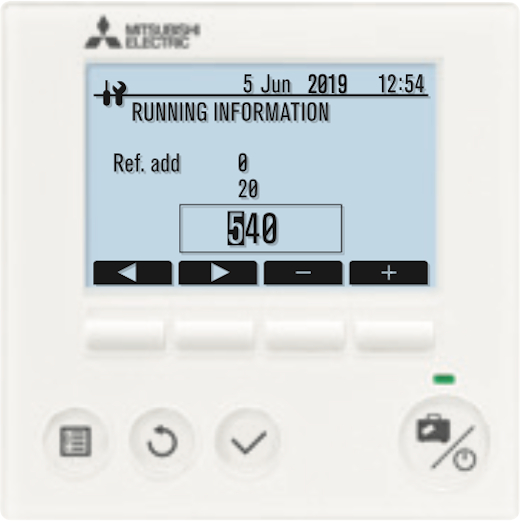

Operation Data Monitoring

Time, operation mode, flow/return/tank temperature, can be displayed on main remote controller.

Minimum Additional Water Required

In average/warmer conditions, minimum additional water is required for outdoor unit. If there is enough water amount inside water pipe, radiator, or underfloor heating no buffer tank is required.

*Refer to the indoor unit installation manual for specific outdoor unit models.

2 Zone Kit

- You can select from 3 types of pump operations, 1. Fixed speed mode, 2. Fixed pressure mode, 3. Energy saving mode, depending on your preference.

- All-in-one kit: Key functional components are incorporated in 2 zone kit.

- Easy installation: G1 screw type flexipiping to avoid brazing.

- Compact size: Just to fit on the top of cylinder unit, also wall mountable.

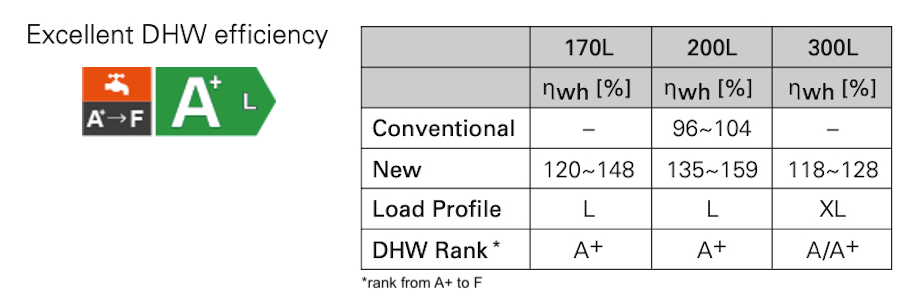

Improved Efficiency

With additional thermistor (THW5A), ηwh [%] rating is improved by more than 40% compared to previous C generation 200L models allowing 170L and 200L to achieve A+, the highest possible domestic hot water efficiency rank.

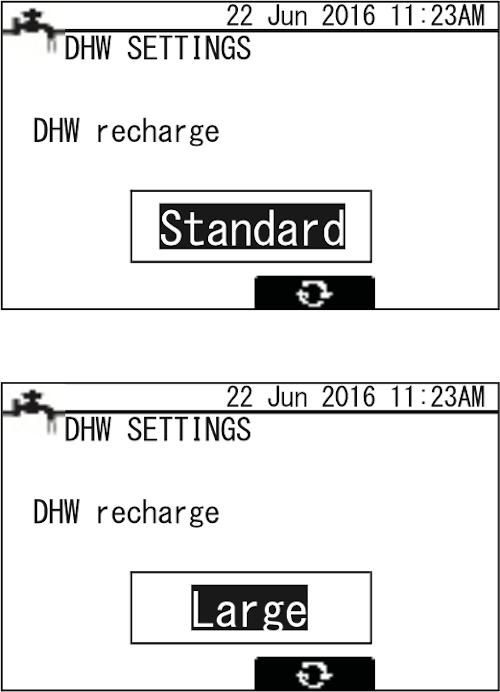

Thermistor Position of Cylinder

The thermistor position is now selectable allowing the unit to accommodate for different water demands in order to maximise the efficiency of the unit for any size of household or application. Using two thermistors equipped with all sizes of tanks, you can now select the DHW recharge amount from two options (Standard/Large). It helps accomodate for different water demands in order to maximise the efficiency of the unit for any size of household or application. This mode can be selected from main remote controller.

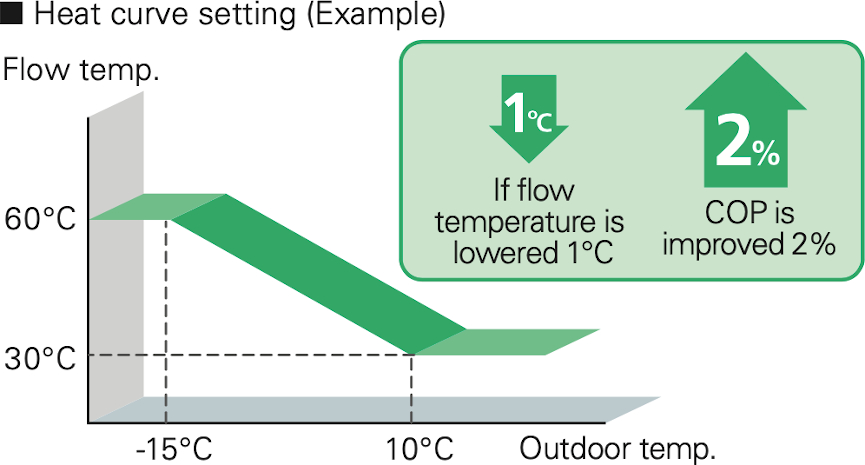

Maximise Energy Savings While Retaining Comfort at All Times

Regarding the relation of flow temperature and unit performance, a 1°C drop in the flow temperature improves the coefficient of performance (COP) of the ATW system by 2%. This means that energy savings are dramatically affected by controlling the flow temperature in the system.

In a conventional system controller, the flow temperature is determined based on the pre-set heat curve depending on the actual outdoor temperature. However, this requires a complicated setting to achieve the optimal heat curve.

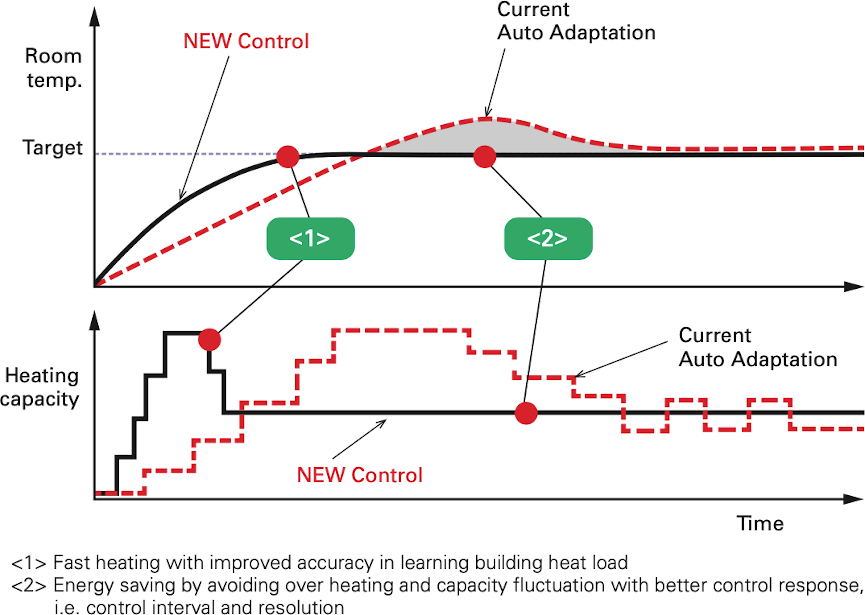

Mitsubishi Electric’s Auto Adaptation Function Automatically Tracks Changes in the Actual Room Temperature and Outdoor Temperature and Adjusts the Flow Temperatures Accordingly.

Aiming to realise further comfort and energy savings, Mitsubishi Electric has already introduced a revolutionary new controller. Auto Adaptation function measures the room temperature and outdoor temperature, and then calculates the required heating capacity for the room. Simply stated, the flow temperature is automatically controlled according to the required heating capacity, while optimal room temperature is maintained at all times, ensuring the appropriate heating capacity and preventing energy from being wasted.

Furthermore, by estimating future changes in room temperature, the system works to prevent unnecessary increases and decreases in the flow temperature. Accordingly, Auto Adaptation maximises both comfort and energy savings without the need for complicated settings. For Mitsubishi Electric ecodan, by introducing improved control logic, we acheived faster heating and more energy saving.

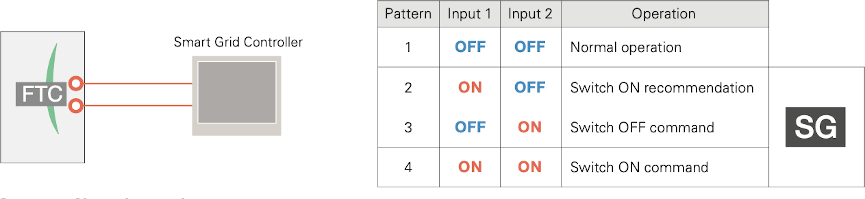

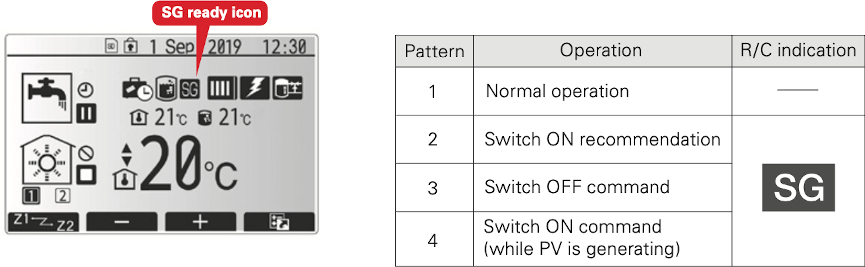

Smart Grid Ready Function

recent years renewable energy generation has become popular. However, this rapid growing causes the problem of supply and demand gap of electricity. The aim of “SG Ready” is to make the electricity demand response more flexible by creating a uniform interface for the smart grid integration of heat pumps. Air-to-Water units need to be able to change the operation pattern when the signal is received from the Smart Grid Controller.

New ecodan Cylinder, Hydro box and FTC have been modified to communicate with Smart Grid Controller. The communication protocol is based on “SG Ready” label regulation. (Version 1.1; gültig ab 01.01.2013)

Pattern 1: Normal operation

When there is no signal from the Smart Grid Controller, DHW and Heating operate according to user settings.

Pattern 2: Switch ON recommendation

When set to the “Switch ON” recommendation, the target temperature of DHW is increased a specified amount and the heating “Thermo ON” condition range is extended.

Pattern 3: Switch OFF command

When the “Switch OFF” command is received, both DHW and Heating are turned off.

Pattern 4: Switch ON command

When the “Switch ON” command is received, the target temperature of DHW is increased to the maximum target temperature and Heating continues.

Improved Smart Grid Ready

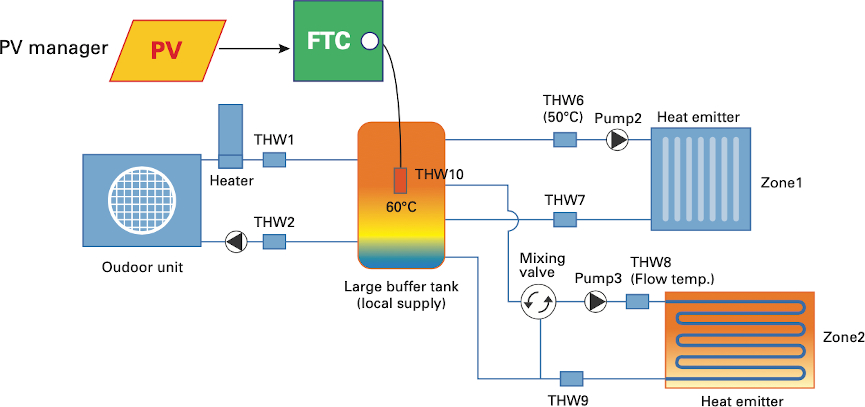

SG ready icon on main remote controller indicates that SG ready is active and its setting can be easily operated with main remote controller. Improved SG ready function enables you to choose the target temperature in unit of 1°C. Also, when PV manager is interlocked with ecodan and ecodan receivers its signal, heat is stored as much as possible while heat pump and/or electric heater running.

Heat storage in large buffer tank will be made available for zone2 as well when peak cut signal is on. As long as a mixing valve keeps its control, zone2 flow temperature is maintained.

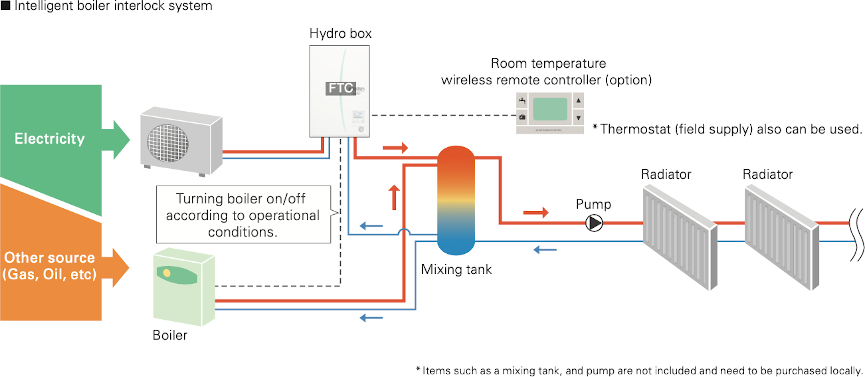

An Existing Boiler Can Be Used for Extra Heating Capacity in an Efficient Way

The flexibility of ecodan’s intelligent control allows the system to be combined with the boiler currently in use. Additionally, this control can judge which heating source to use either ecodan or the existing boiler, based on various conditions*.

In the event of one heating unit not working due to some unforeseen problem, the other heating system can be used as a back-up, thereby preventing the heating system operation from stopping completely.

*Please see below “Heat source switchover”.

Intelligent system combining a boiler with ecodan

Heat source switchover - Choose appropriate system based on needs

4 types of heat source switchover logic

- Switchover based on actual outdoor temperature

- Heat source switchover occurs when the outdoor temperature drops below a pre-set temperature

- Switchover based on running cost

-

Heat source switchover occurs by judging optimal operation based on running cost.

*Pre-registration of the energy price of electricity, and gas or oil per 1kWh is necessary.

- Switchover based on CO2 emission level

-

Heat source switchover occurs to minimise CO2 emission.

*Pre-registration of CO2 emission amount from electricity and gas or oil is necessary.

- Switchover can also be activated via external input

- For example, the peak cut signal from electric power company.

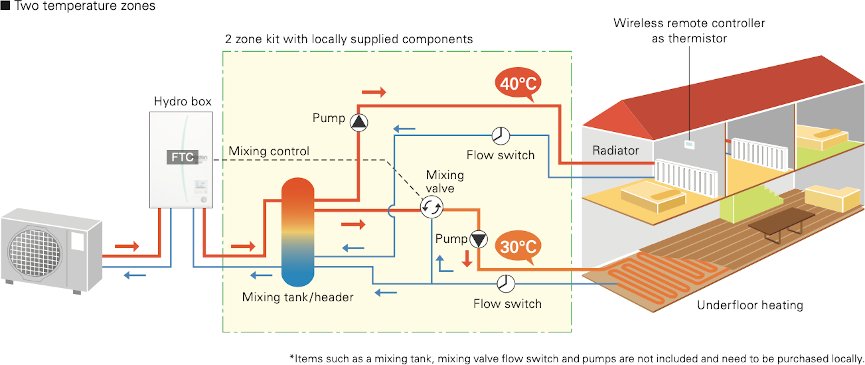

Improved Simultaneous Control of Two Different Zones

Using ecodan, it is possible to control two different flow temperatures, thereby managing two different heating load requirements. The system can adjust and maintain two flow temperatures when different temperatures are required for different rooms; for example, controlling a flow temperature of 40°C for the bedroom radiators and another flow temperature of 30°C for the living room floor heating.

Moreover, mixing valve control is advanced for improving zone 2 comfort by using heat storage in buffer tank. Also, new controller monitors the temperature inside buffer tank and prioritizes using the heat inside the tank to avoid frequent on/off operation when using 2 zone control.

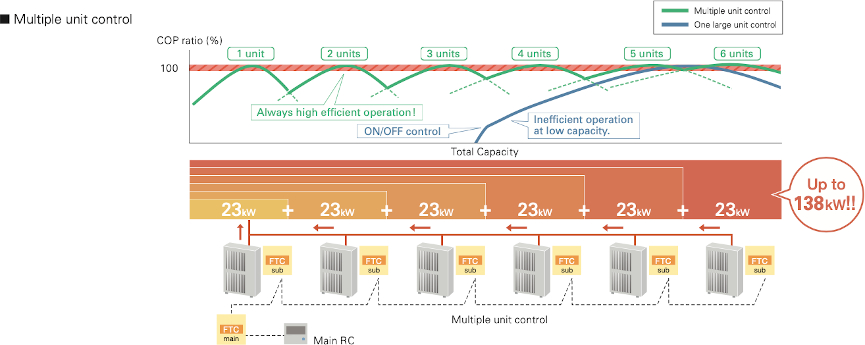

Connect up to 6 Units – Automatic Control of Multiple Units for Bigger Capacity and Better Efficiency

A maximum of 6 units* can be configured according to the heating/cooling load of the building. The most efficient number of operating units is determined automatically based on heating/cooling load. This enables ecodan to provide optimal room temperature control, and thus superior comfort for room occupants. Also incorporated is a rotation function that enables each unit to run for an equal time period.

If one of the units malfunctions when using the Multiple Unit Control, another unit can be automatically operated for back-up, thereby preventing the system operation from stopping completely.

*Only same models (same capacity) can be used.

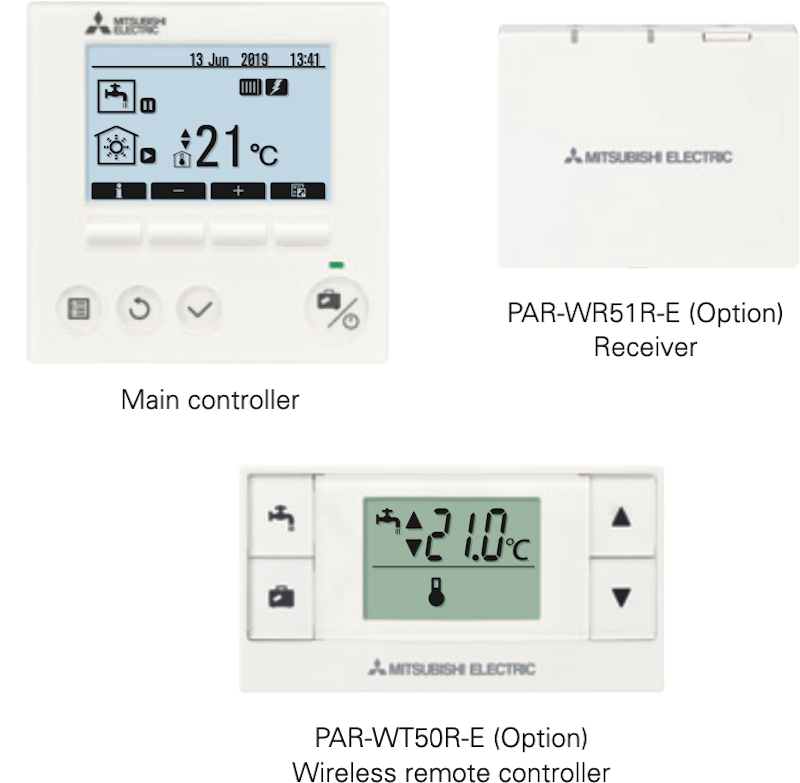

Smart User-friendly Controller with Stylish Design

Main remote controller

- Large screen and backlight for excellent visibility, even in dark environment

- Multi-language support (supports 15 languages)

- Can be removed from main unit and installed in a remote location (up to 500m) • Quick reading of operation data (7.5 times faster than previous model)

- Wide range of convenient functions in response to user demand

Function settings

- Energy monitoring

- Two-zone control (cooling and heating) – Two separate schedules

- Summer time setting

- Built-in room temperature sensors

- Hybrid control (boiler interlock)

- Floor drying mode

- Weekly timer

- Holiday mode

- Legionella prevention – Error codes

Wireless remote controller (optional)

- Built-in room temperature sensor; easy to place in the best position to detect room temperature

- Wiring work eliminated

- Simple design that is easy to operate

- Remote control from any room without needing to choose an installation location

- Backlight and big buttons that are easy to operate • Domestic hot water boost and cancellation

- Simplified holiday mode

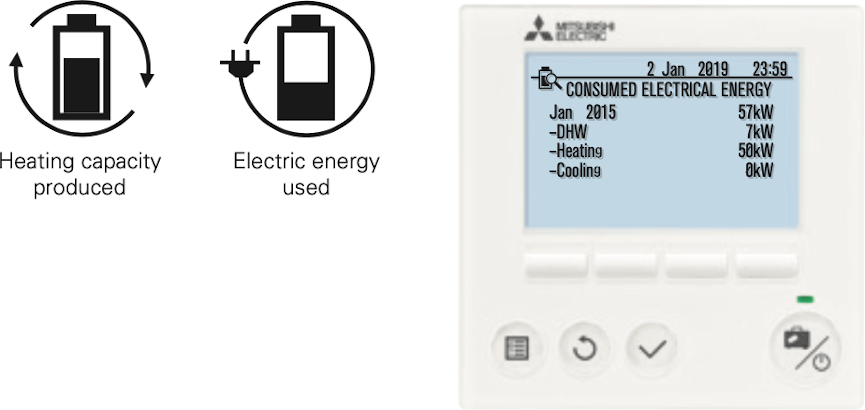

View Electricity Consumption and Heat Output on the Remote Controller

Every end user can now easily check the energy data of the ecodan heat pump.

Other features

- Daily, monthly and yearly data are stored and can be displayed using the main remote controller.

- External power meter and heat meter can be connected for accurate measurement.

- SD card is also available for storing data.

Using pre-set values on the main remote controller, estimated energy consumption/output can be shown without external power and a heat meter.

Depending on operating condition and system configuration, there is some possibility to show different data from the reality.

*This function is available depending on the version of the outdoor unit model.

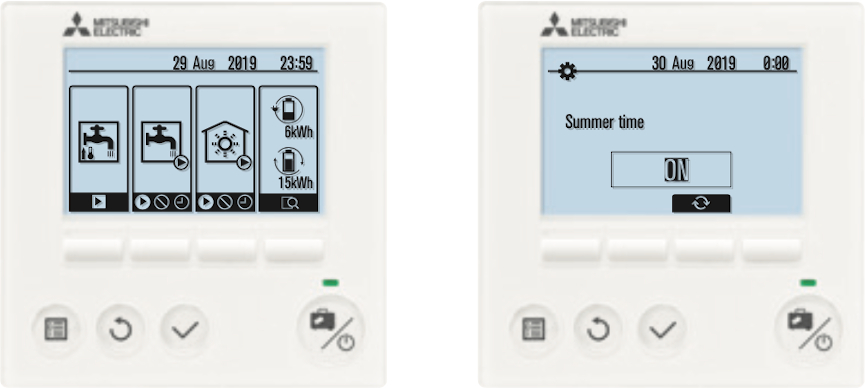

Easy Adjustment for Summer Time

Just switch the summer time mode ‘on’ using the main remote controller and the clock in the main remote controller is adjusted to summer time hours.

This function can release the end user from clock setting tasks.

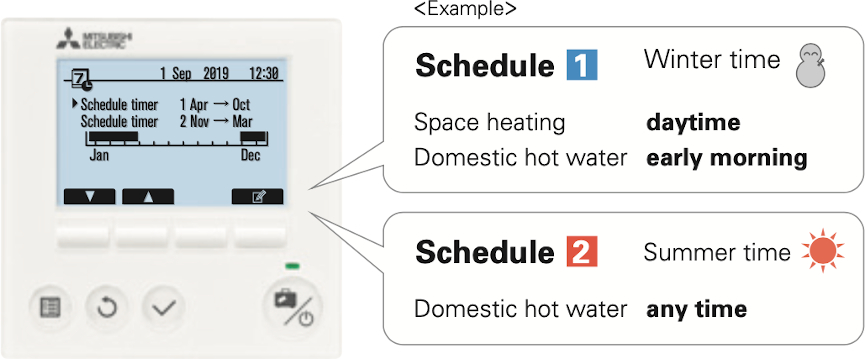

Pre-setting Two Different Schedules for Winter and Summer Seasons

Two different schedule settings are available for use via the main remote controller.

These schedules can be pre-set and changed depending on the season. For example, from November to March, space heating and domestic hot water are used; however, during warm months such as from April to October, only domestic hot water is used.

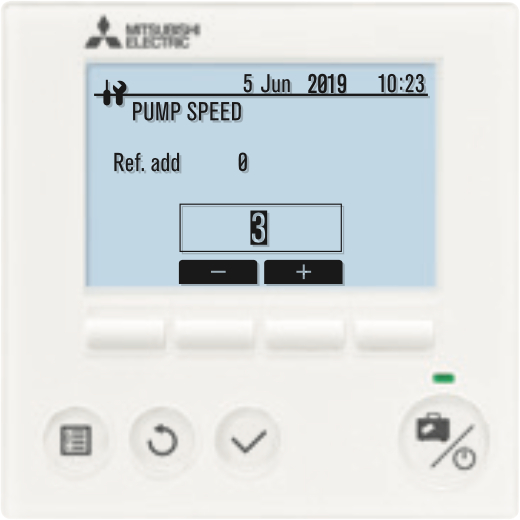

Pump for Primary Water Circuit* Speed Setting Possible Using ecodan’s Main Remote Controller

Even when the system is running, pump output can be set to one of five different settings using the main remote controller.

The person commissioning the system can adjust this speed much more easily.

*Speed setting of pump for domestic hot water is not available through the main remote controller when the system is running.

Flow sensor newly incorporated

The flow sensor is key for monitoring energy output and can also be used to detect flow error as well.

- Flow rate can be checked on the main remote controller.

- Flow rate can also be shown as graphs using the SD card tool.

Run indoor unit* without outdoor unit

During installation or situations such as an outdoor unit malfunction, the indoor unit can be operated using a heater. While using this mode, flow and tank temperature are selectable. Fixing and maintenance of the outdoor unit can be done without stopping heating and domestic hot water operation*.

*Models with electric heater only.

*When the indoor unit operation stops, please check all settings after the outdoor unit is connected.

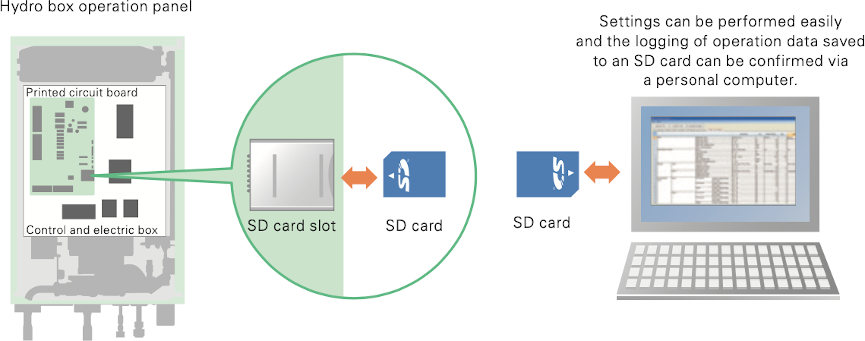

For Easier Settings and Data Logging

The initial setting for ecodan is now simpler than ever before. The special software enables the required initial settings to be saved to an SD card using a personal computer. The system set-up is as easy as moving the SD card from the computer to the SD card slot in the indoor unit. Compared to the previous procedure of inputting settings using the main controller at the installation site, a remarkable reduction in set-up time has been achieved. Thus, it is ideal for busy installers.

*SD card function is only used at the time of installation.

Items that can be pre-set

Simply copying pre-set data to an SD card, the same settings can input into another unit using the SD card.

- Initial settings (time display, contact number, etc.)

- Heating settings

- Auto adaptation

- Heat curve

- Two different temperature zones (heating and cooling)

- Interlocked boiler operation settings

- Holiday mode settings

- Schedule timer settings (two separate schedules) • Domestic hot water settings

- Legionella prevention settings

All items that are set by the main controller can be set via a personal computer.

Data that can be stored

Operation data up to a month long can be stored on a single SD card

- Consumed electrical energy

- Delivered energy

- Flow rate

- Operation time

- Defrost time

- Actual temperature

- Room temperature

- Flow temperature

- Return temperature

- Domestic hot water temperature – Outdoor temperature

- Error record

- Input signal

- Etc.