Complete system

HVRF Y systems are based on a modular concept and a complete solution of Mitsubishi Electric branded products.

All system components: Outdoor Units, Hydronic Units, Indoor Units, Control Systems are native to Mitsubishi Electric and communicate with each other through the “M-Net” communication system.

The regulation of HVRF systems is also Mitsubishi Electric unlike traditional Hydronic systems.

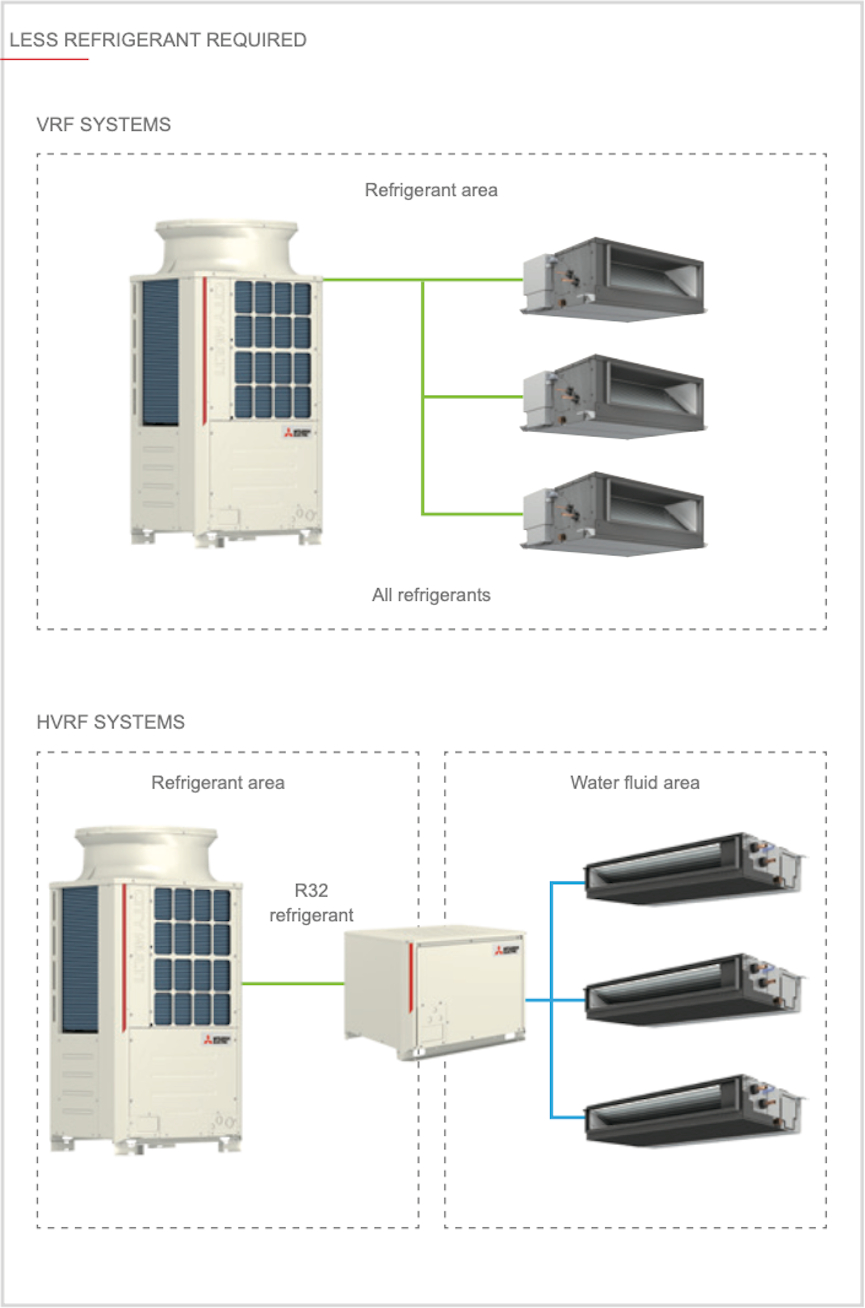

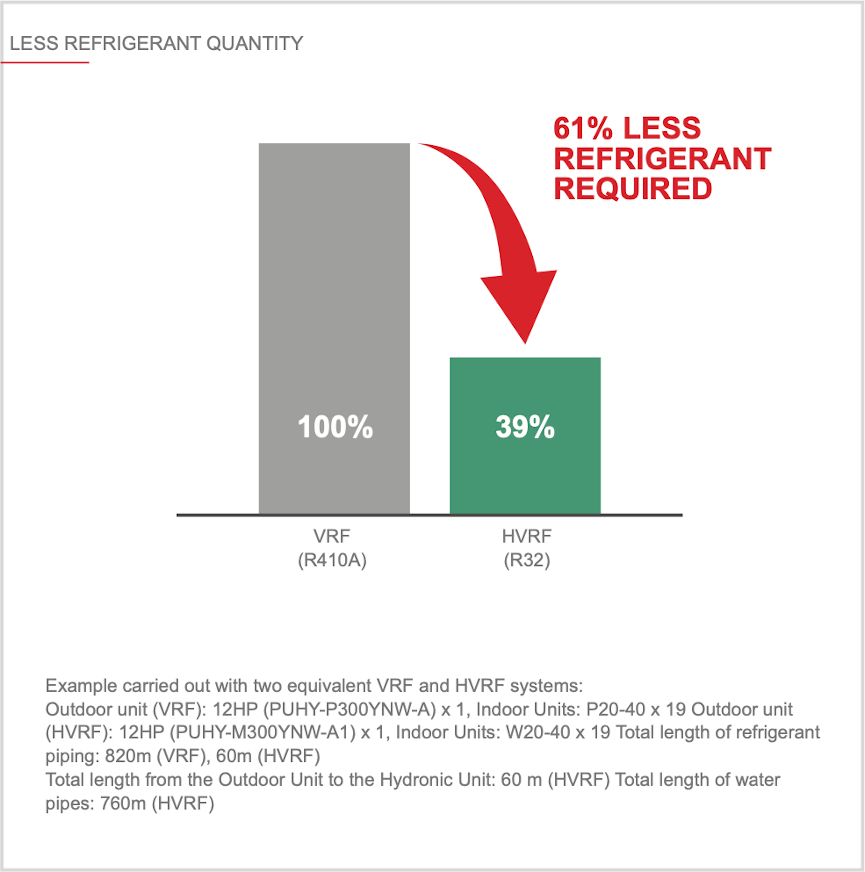

Less refrigerant required

The hydronic unit creates a separation between the area delimited by the refrigerant and the area delimited by the water fluid, limiting the amount of refrigerant that was measured to be around 61%.

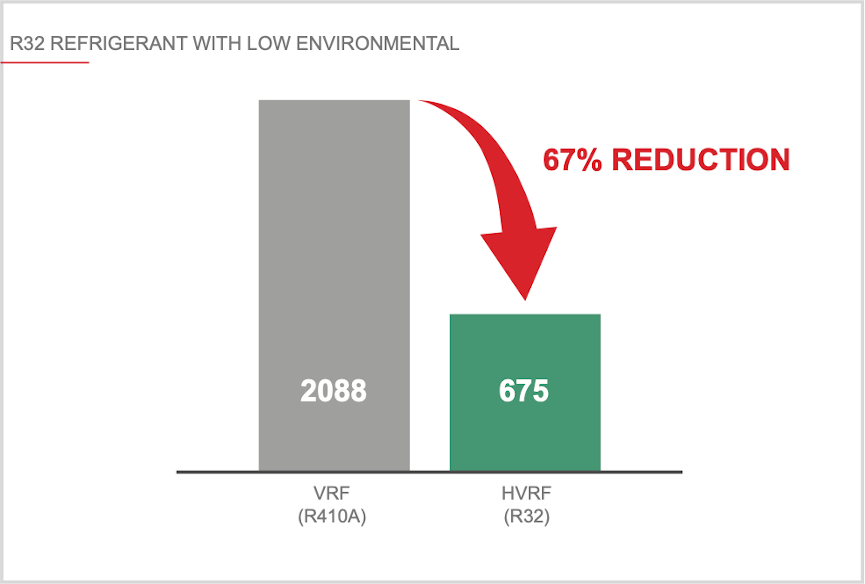

R32 refrigerant with low environmental impact

Starting from the HVRF Y range, Mitsubishi Electric chooses R32 gas with low GWP (“global warming potential”) 675, approximately 67% less than the 2088 value of R410A gas.

The advantage is in terms of a net reduction in the amount of CO2 equivalent in the environment. Adding the benefits of 61% less refrigerant and 67% less GWP, the reduction amounts to 87% for the CO2 released in the environment.

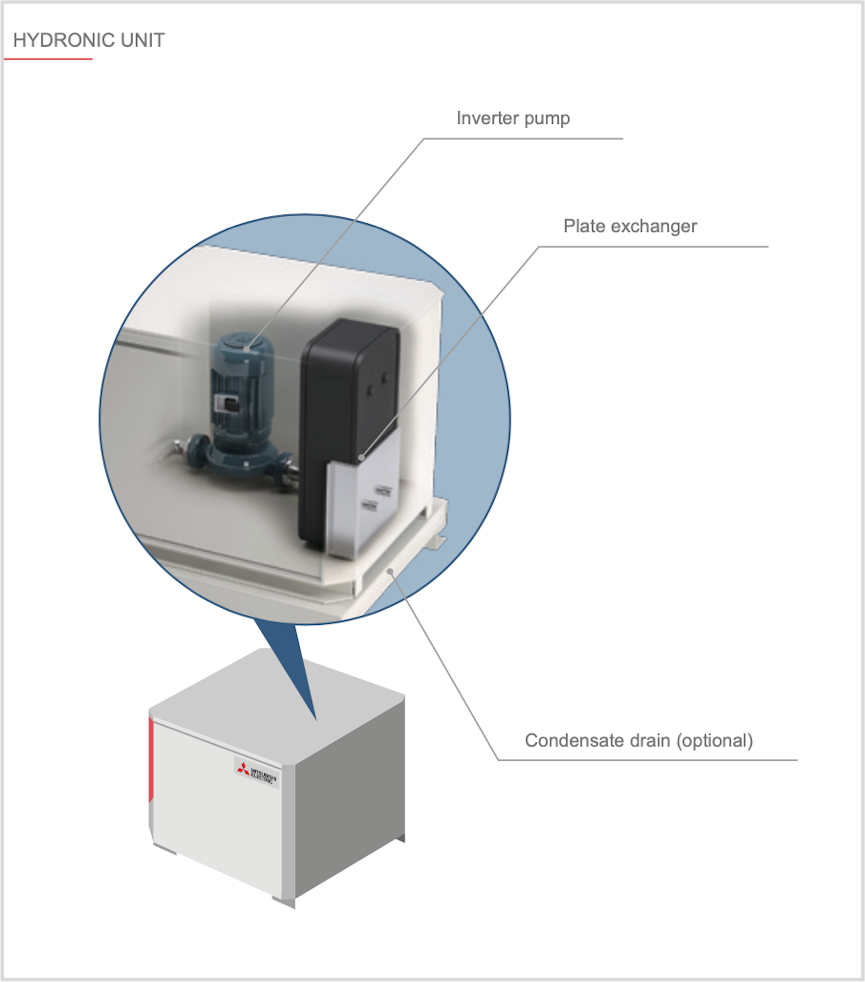

Hydronic unit

The hydronic unit is the fundamental element of the HVRF Y heat pump system, it connects the CITY MULTI outdoor unit to the indoor units via the hydronic system.

The integrated plate exchanger exchanges heat between refrigerant and water.

The integrated pump regulated by an inverter allows the water to reach the indoor units according to the actual cooling and heating needs, allowing efficient operation.

The R32 refrigerant pipes are limited in the section between the Outdoor Unit and the Hydronic Unit, helping to reduce the amount of refrigerant compared to VFR CITY MULTI systems.

The HVRF Y system’s hydronic unit can be installed in the building, making the use of antifreeze unnecessary. This reduces energy consumption compared to traditional chillers.

Optimal control

The Hydronic unit automatically calculates the water flow rate required for all indoor units by adapting the flow according to the required load. The pump is controlled with the inverter to determine the amount of water according to the internal load.

The optimal temperature of the supply water is automatically calculated and the corresponding command is communicated to the outdoor unit to define the evaporation and condensation target for the refrigerant gas production.

Outdoor unit

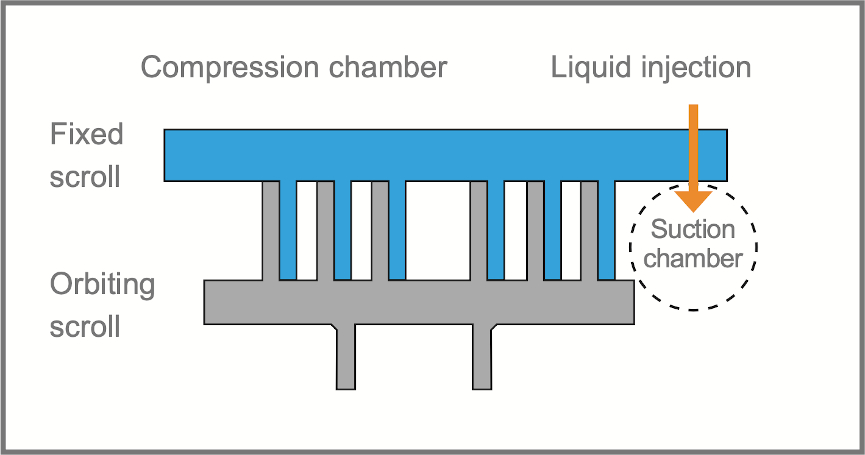

Development of the compressor for the adoption of R32 refrigerant

R32 gas has a higher discharge temperature than R410A gas.

To better manage the increase in the discharge temperature, Mitsubishi Electric has redesigned the compressor by equipping it with a liquid injection mechanism in the suction chamber.

Control systems

System control through M-NET

Mitsubishi Electric outdoor unit, indoor units, hydronic unit and individual and centralised control systems communicate through the M-Net communication system for optimal control of the entire system.

Indoor unit

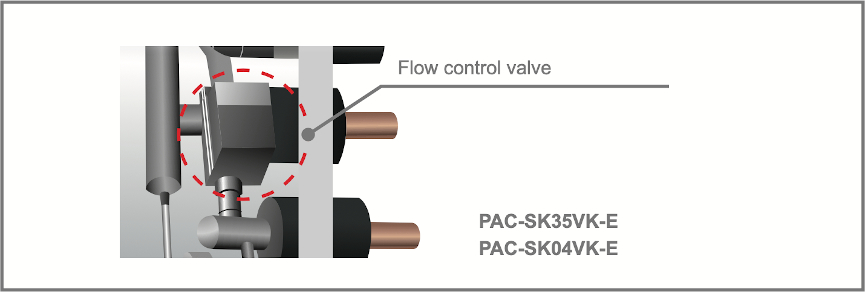

Optimal control with the flow control valve

HVRF Y system indoor units are fitted with a flow control valve. Based on the internal load of each room, opening the valve automatically allows the correct supply of water to the indoor units serving each room.

Documentation

General Catalog

Comfort & IT Cooling Systems - Full product catalogue 2024

Download