M SERIES

- 4-way cassette

- 3D i-See Sensor

- Horizontal flow

- Silent

- compatible with Plasma Quad Connect

3D i-See Sensor

4-way

Cassette

Efficiency

Optional filters

Standard filter

R32 refrigerant gas

R410A refrigerant gas

Air heating/cooling

The ideal 4-way cassette for a wide range of installations in commercial and office buildings. The horizontal air flow, individually controlled vanes and possibility of installing the 3D i-See Sensor ensure maximised ambient comfort.

Technical characteristics

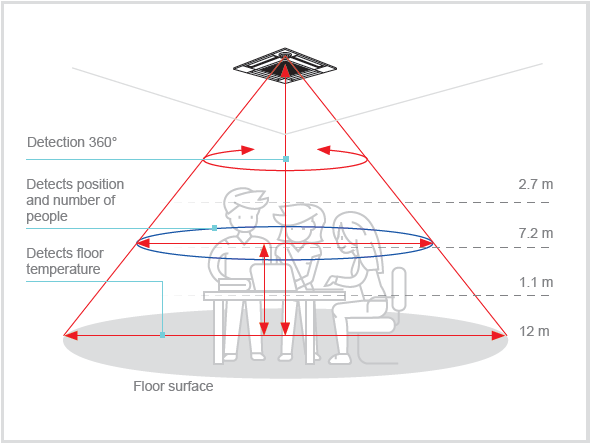

3D i-See Sensor

Temperature sensor

The 3D i-See Sensor measures the temperature at floor level in the air conditioned indoor space to ensure that the air flow is directed effectively towards the more critical areas of the room. Specifically, the deflectors aim towards zones with higher floor level temperatures in cooling mode and towards the zones with lower floor level temperatures in heating mode.

Direct/indirect flow function

The new 3D i-See Sensor system (optional) detects the number of persons in the air conditioned indoor space and their precise positions in the room. When active, the Direct/Indirect function lets the user decide whether or not the air flow is directed towards the zones where persons are detected. The Direct/Indirect function is selectable individually for each of the four deflectors.

All the functions offered by the 3D i-See Sensor are also available with the PAC-SE1ME-E 3D i-See Sensor corner panel. In this case, the MA controller [PAR40(41)MAA] or PAR-SL 100 A-E infra-red controller are also necessary.

Energy savings

The energy-saving functions available when using the 3D i-See Sensor let you optimise ambient comfort while minimising energy wastage. The occupancy sensor automatically reduces the thermal power delivered to the indoor space in relation to the degree of occupancy of the space itself. The exclusive capability of the new 3D i-See Sensor to determine the number of persons in the indoor space makes it a particularly advantageous solution for all environments (such as public spaces, restaurants, business offices, shops etc.) where the number of occupants can vary significantly.

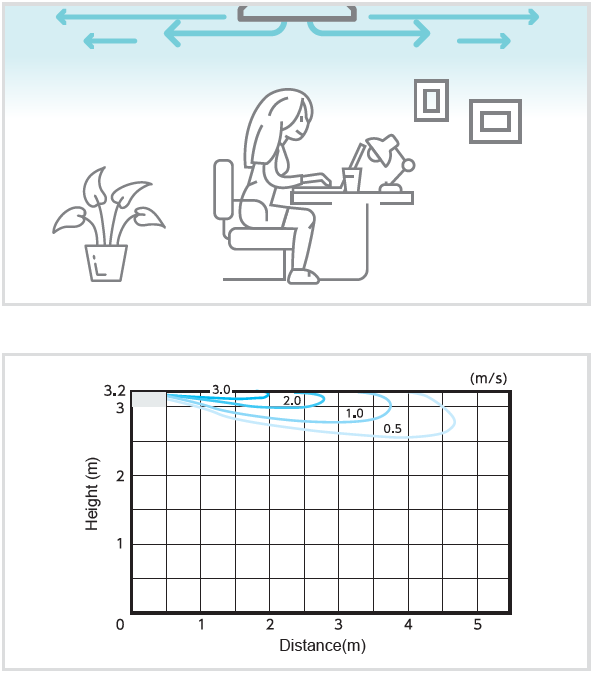

Horizontal flow

The new indoor unit features the "horizontal flow" function, which projects the air along the surface of the ceiling, increasing the sensation of comfort perceived by the occupants.

Optimum air flow

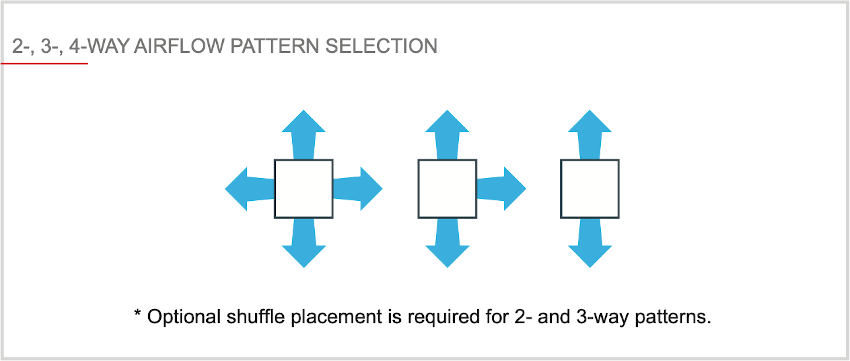

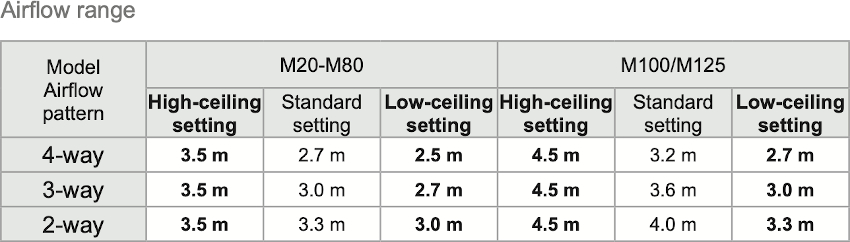

Choice of 2, 3 or 4-way air flow configurations

To cater for the needs of different installation scenarios, a choice of three air outlet configurations is offered: two-way, three-way or four-way. For instance, the four-way configuration may be selected for installation at the centre of a room, whereas the three-way option is ideal for installation in corners.

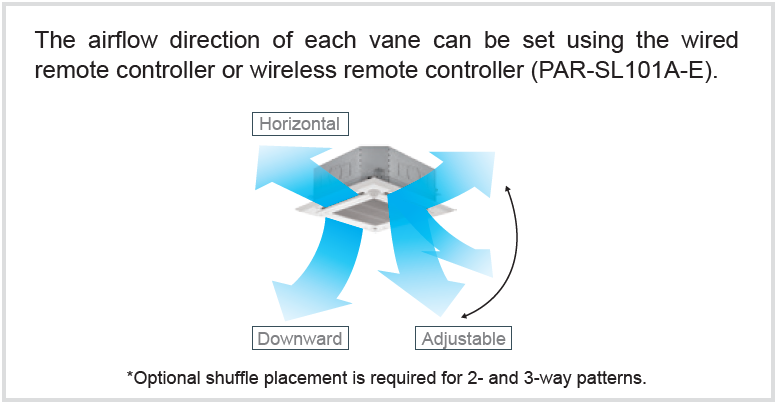

Individual deflector angle settings

The direction of the deflectors can be set from the remote control to direct air towards or away from objects and persons in the room.

Individual deflector angle settings

The countless combinations offered by the ability to set each deflector individually lets you configure the perfect air distribution solution for each room and ensure uniform temperature distribution throughout the entire indoor space. The result is pleasant, uniform air conditioning.

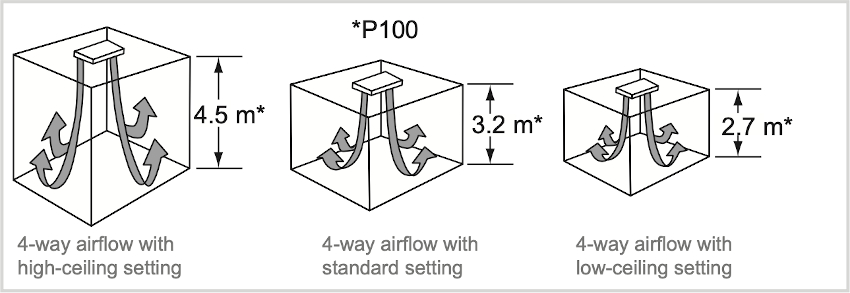

Different modes for high and low ceilings

Adaptable to the height of the room

These units feature different modes for use with high or low ceilings, which optimise the volume of the air flow to the effective height of the room. Being able to choose the volume contributes to improving perceived air conditioning comfort throughout the whole room.

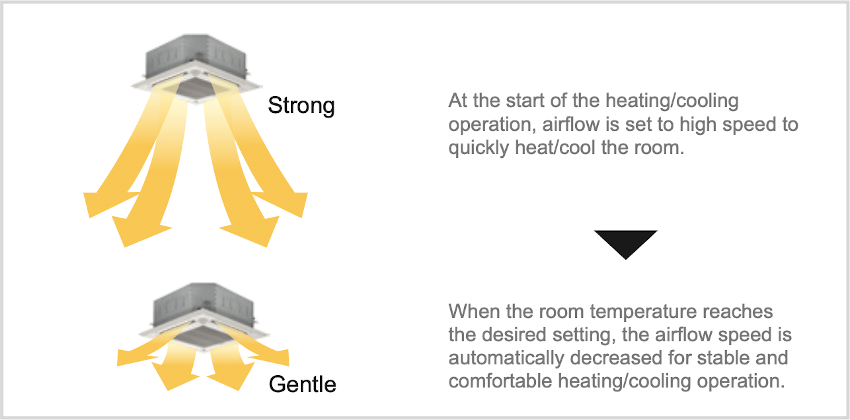

Automatic air speed adjustment

Automatic air speed adjustment

An automatic mode regulates the air flow to maintain ideal levels of ambient comfort at all times. This function lets the unit autonomously adjust air flow speed in relation to the environmental conditions in the room.

Grille and controls

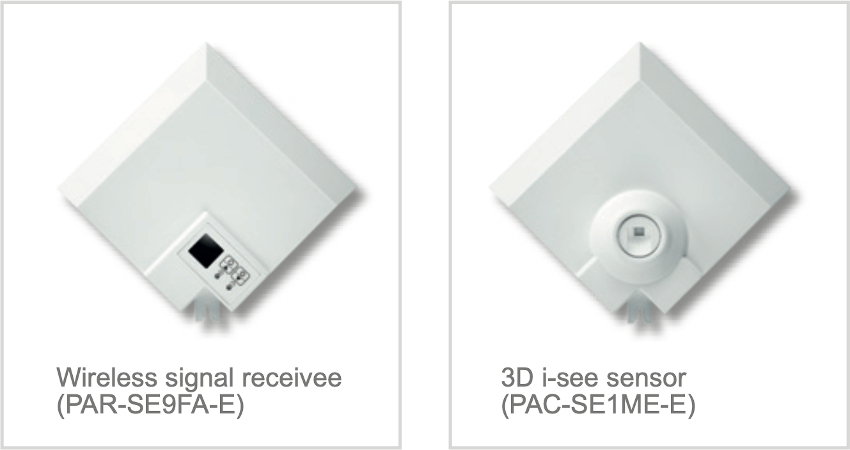

Signal receiver

The unit is equipped as standard with the PLP-6EA grille with no signal receiver. The signal receiver (PAR-SE9FA-E) is available as a corner panel, like the 3D i-See Sensor (PAC-SE1ME-E). As standard, the unit comes without a remote controller. This unit may be operated with all MA and ME wired controllers and (if a signal receiver is installed) with wireless remote controllers. Using the new PAR-SL101A-E remote controller, which features a weekly timer, backlit display, temperature setting function in 0.5 °C steps and individual control for 4 deflectors, lets you make use of all the functions of the optional 3D i-See Sensor. The new PLP-6EAB black panel is now also available as an accessory. 3D i-See Sensor not included, and with no infra red signal receiver.

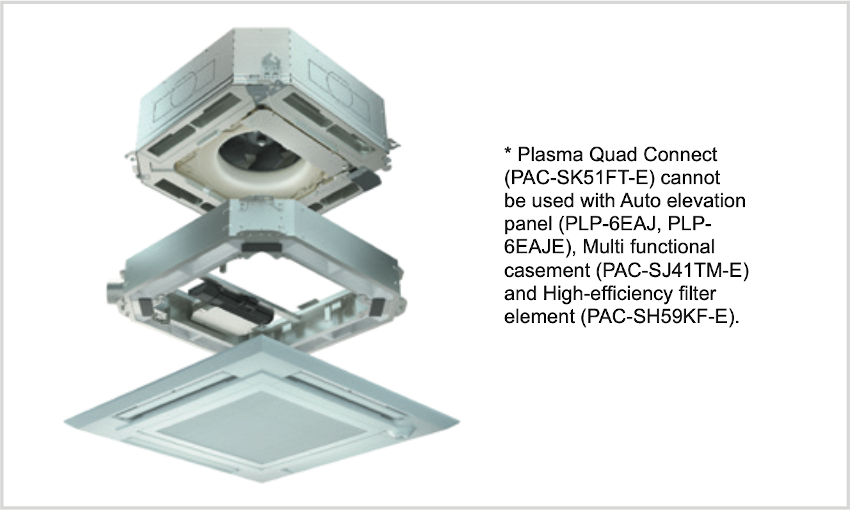

Compatible with Plasma Quad Connect

The optional Plasma Quad Connect filter (PAC-SK51FT-E) may be installed on this unit.

Simplified installation

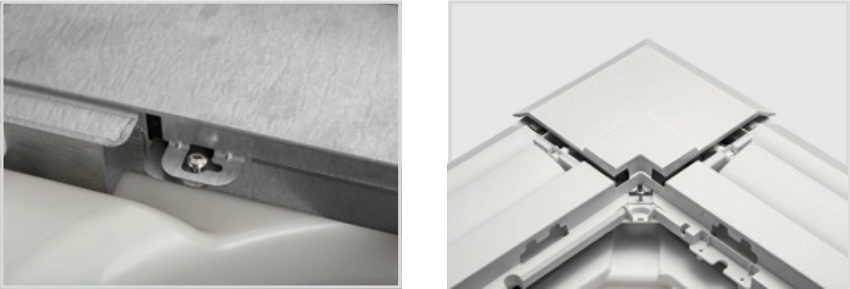

Simplified installation

The temporary grille mounts, which hold the grille in place while the component is fastened, make installation of the unit quicker and easier.

The redesigned structure and new material used for the manufacture of the grille reduce the weight of the grille by 20% compared with the previous model, contributing to reducing the total load installed.

Installation is possible by simply loosening the fastener screws for the control box and removable corner panel without removing the screws completely. This minimises the risk of dropping and losing the screws themselves.

Documentation

General Catalog

Comfort & IT Cooling Systems - Full product catalogue 2024

Download