Bringing a year round comfort solutions to extreme climates

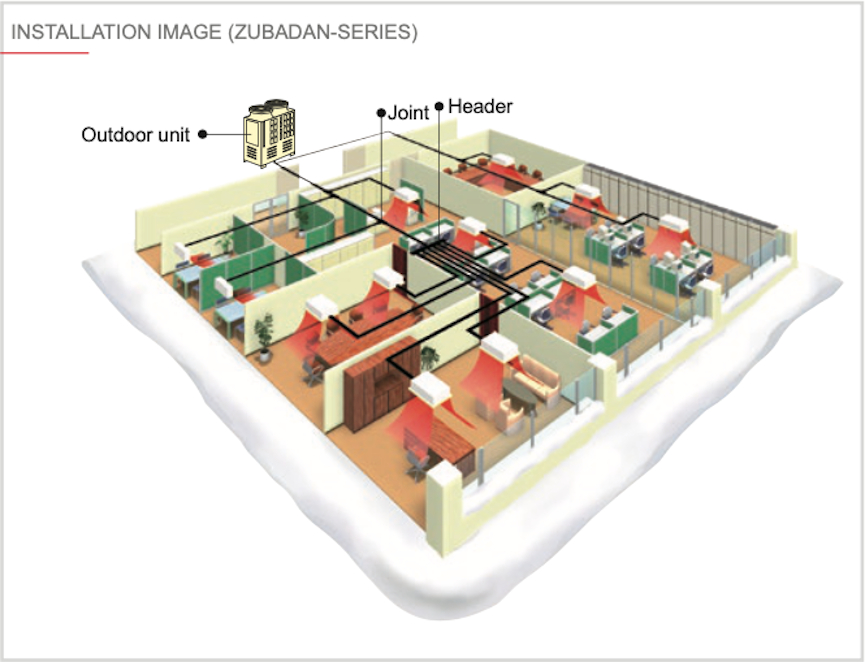

CITY MULTI ZUBADAN-Series combines the ultimate in application flexibility and powerful cooling and heating capabilities to deliver precise comfort even in the coldest days of the year down to -30°C.

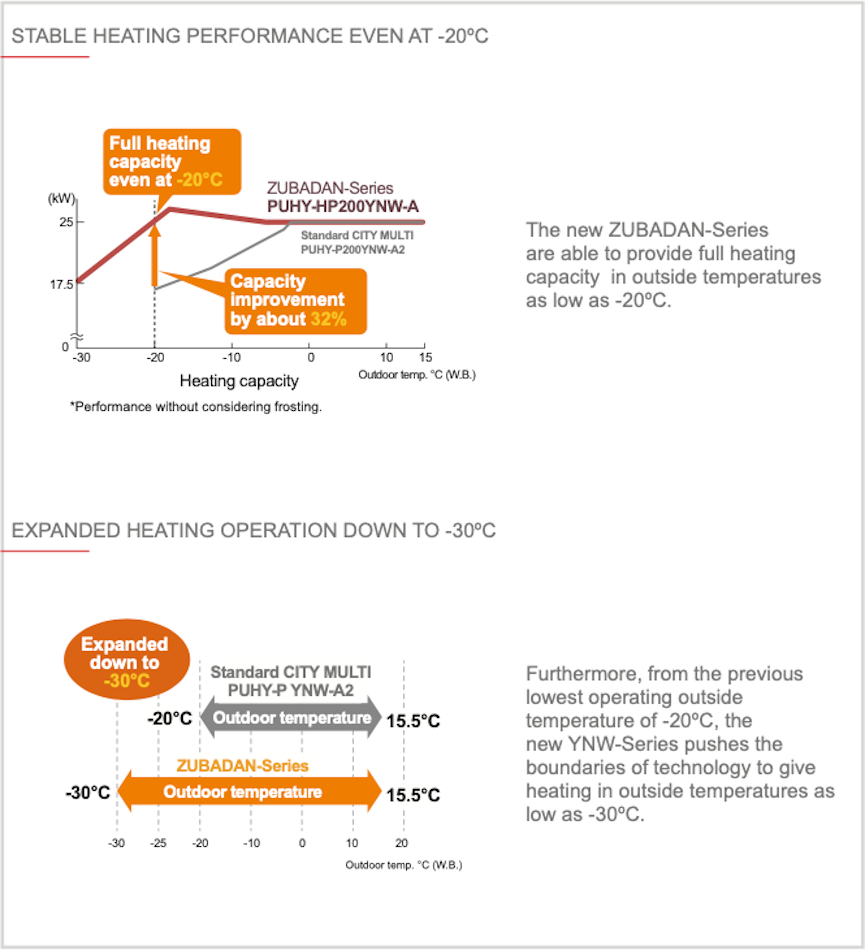

The new ZUBADAN-Series that has new, larger-capacity compressors with an injection function in the suction chamber is capable of running at the rated heating capacity down to -20°C. In addition, the guaranteed outside temperature range of heating operation is expanded down to -30°C.

Reliable heating performance

The improved operating performance in low outside temperatures contributes to comfortable heating in cold weather.

Energy saving

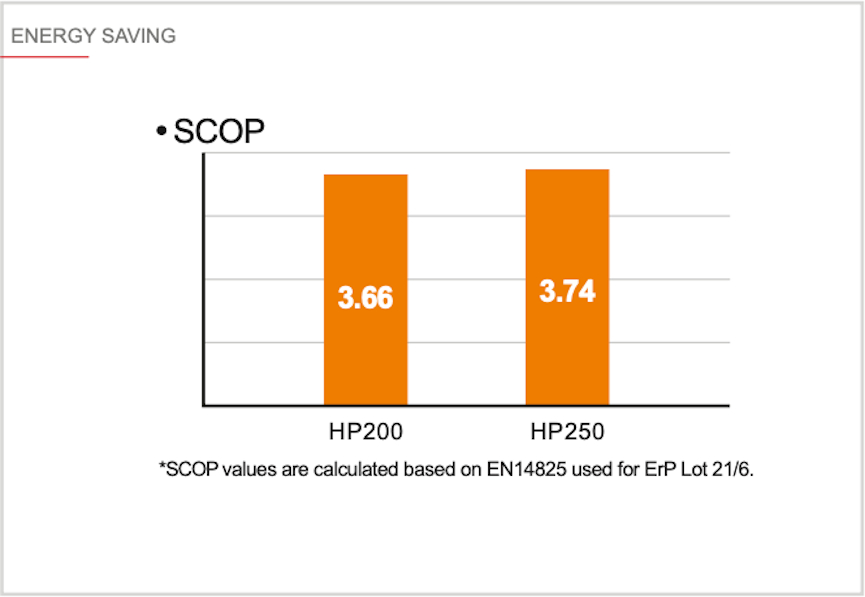

The ZUBADAN-Series delivers high energy-saving performance throughout the year. The improved compressor with the latest technologies realizes both reliable performance and highly efficient operation.

Furthest piping length The highest SCOP 3.74 is achieved by the HP250 model.

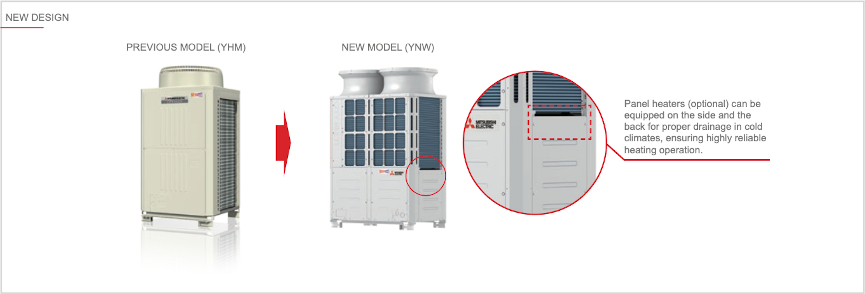

New design

The structure and design have been revised. The appearance is more sophisticated which can enhance the design of building.

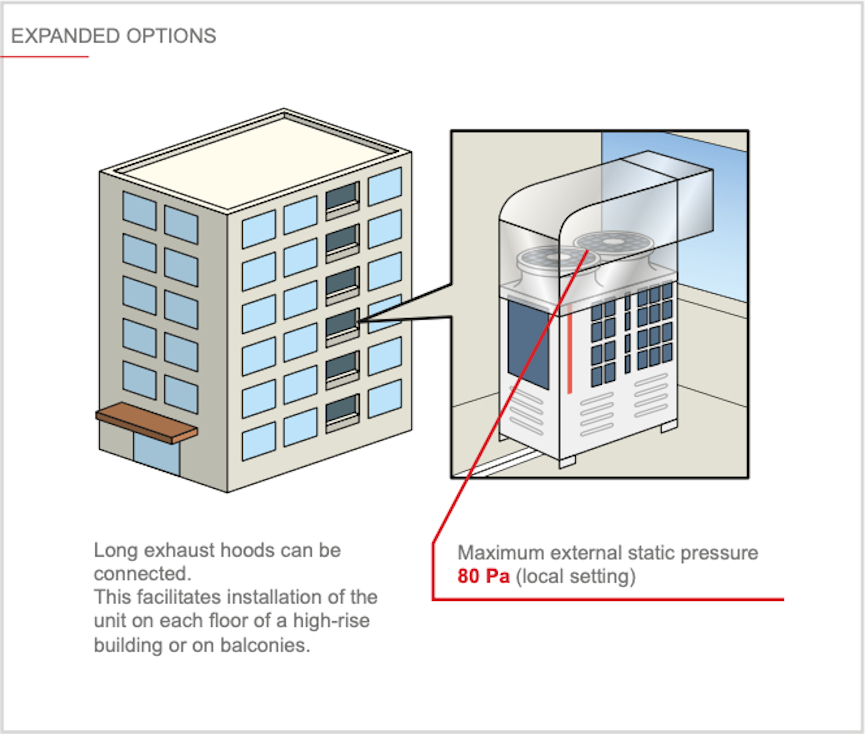

Expanded options for external static pressure settings

The new models (YNW) offer the static pressure options of 0, 30, 60, and 80 Pa, while previous models (YHM) had maximum external static pressure of 60 Pa. This facilitates installation of the unit on each floor of a high-rise building or on balconies.

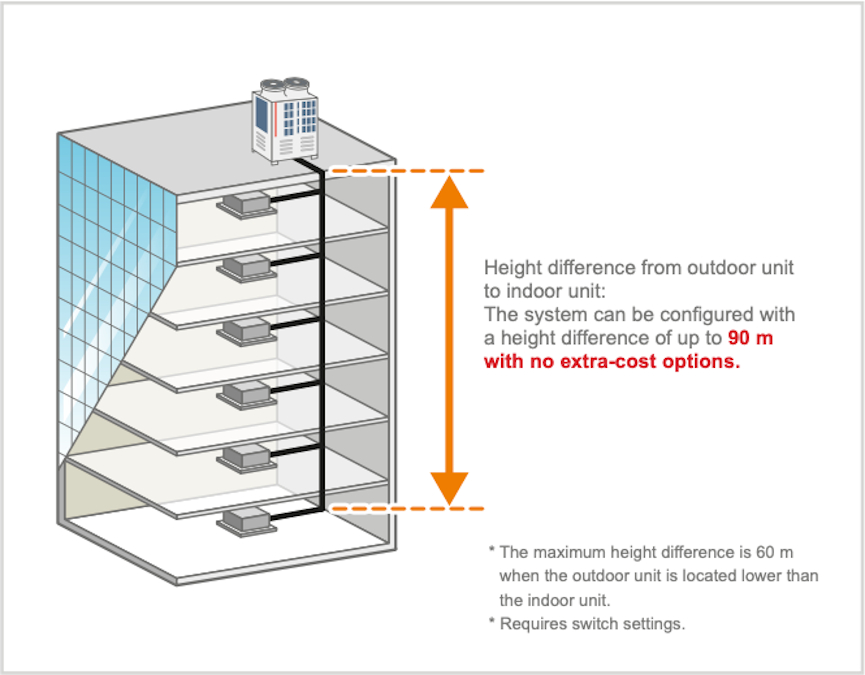

Usable in an application with a large vertical separation of up to 90 meters

A height difference of up to 90 m from the outdoor unit to the indoor unit can be supported with no extra-cost options.

This increases design flexibility and facilitates installation of these units even in high-rise buildings.

Change refrigerant oil of compressor

The new ZUBADAN-Series uses MEL46EH refrigerant oil instead of the conventional MEL32, for greater resistance to low temperatures and steady circulation even in cold environments.

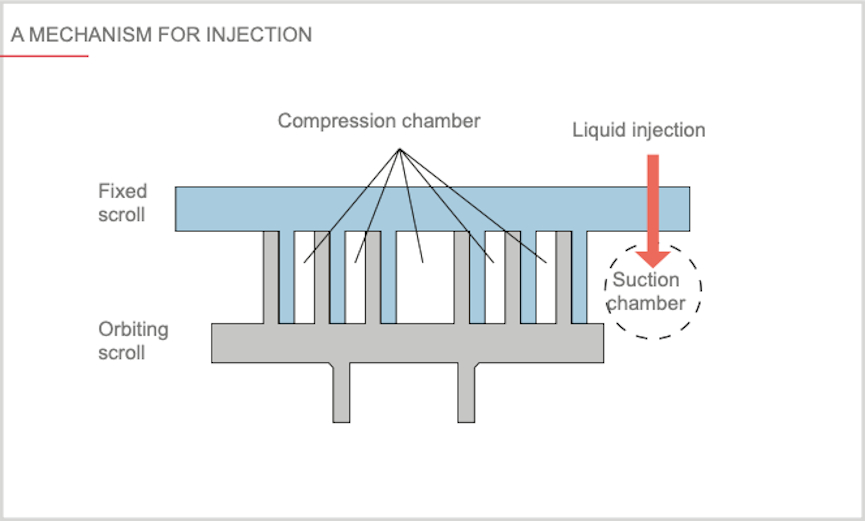

Suction chamber injection mechanism

The reliable heating operation of ZUBADAN-Series is supported by a suction chamber injection mechanism. This mechanism injects liquid refrigerant into the suction chamber and suppresses the temperature rise of the discharge gas. Owing to this technology, the ZUBADAN-Series can perform heating operation even at an outside temperature as low as -30°C. Furthermore, heating performance at low outside temperatures is improved, because the rated capacity is maintained even at outside temperatures down to -20°C.

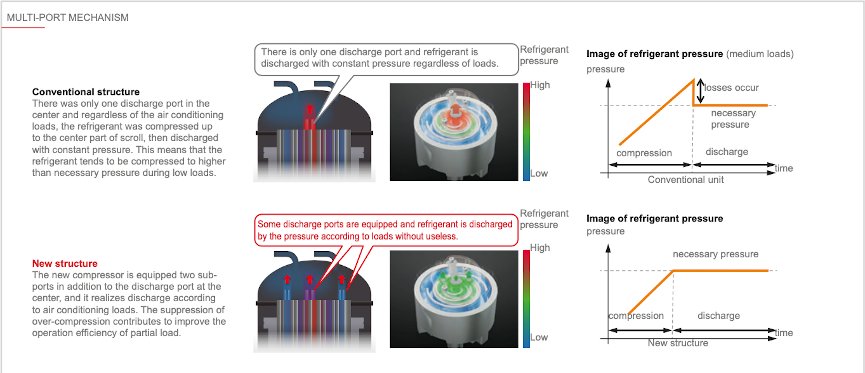

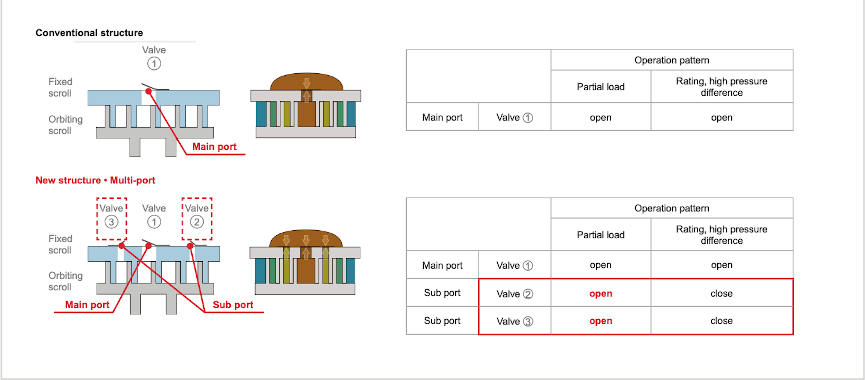

Multi-port mechanism

Efficient partial load operation is realized by avoiding overcompession. With the scroll compressor, the distance of the compression process in the scroll is usually fixed, so over-compression occurs during low loads and low rotation. The new compressor is equipped two sub-ports in addition to the conventional discharge port to reduce this over-compression loss during low loads. In operation conditions having a low compression rate, the distance in the compression process is kept short by that successfully avoiding unnecessary compression, and contributing to efficient partial load operation.

The new structure, multi-port compressor which newly equipped two sub-ports which open and close according to loads, discharges refrigerant from sub-port during the partial load operation.

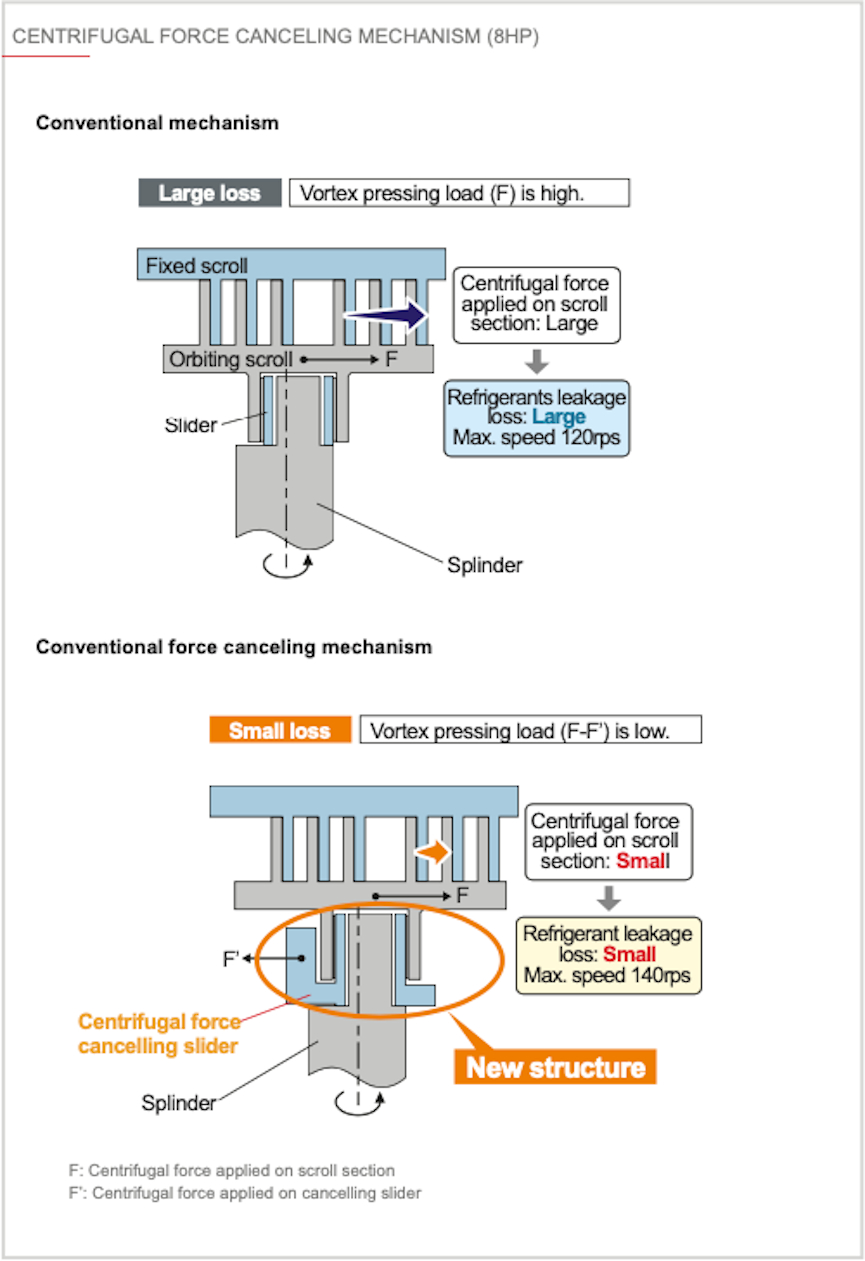

Centrifugal force canceling mechanism (8HP)

The latest structure has been mounted to suppress the centrifugal force. This mechanism successfully suppresses the centrifugal force generated at the scroll section, reduces refrigerant leakage losses, and increases the compressor efficiency. The maximum rotational speed has been increased from the conventional 120rps to 140rps.

This mechanism also speeds up the start of operation, and enables operations such as preheat defrost and the smooth auto-shift startup mode.

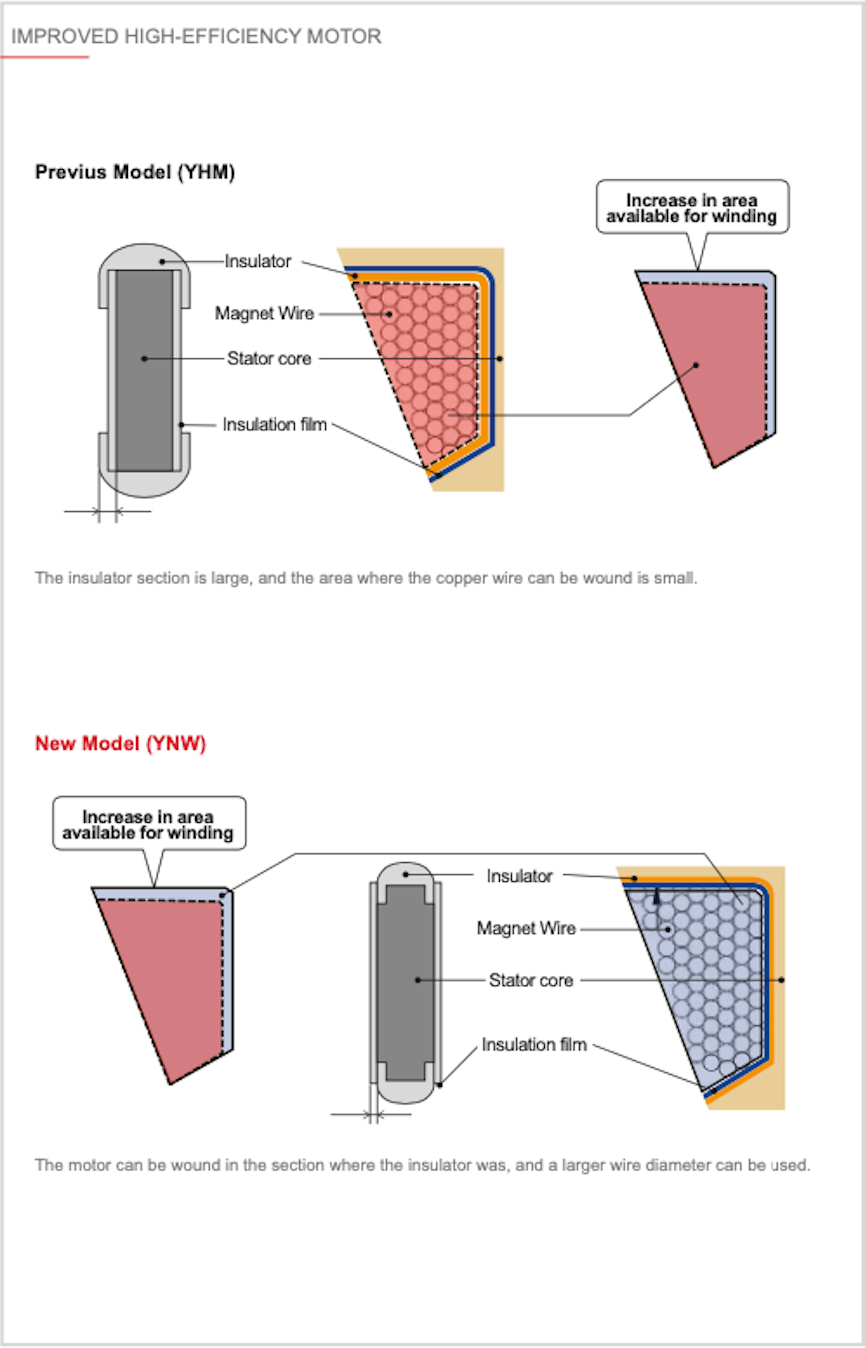

Improved high-efficiency motor

The insulator section that traditionally created a dead space is eliminated by insulating the motor’s stator film. Since winding can be set in that section, the winding area can be increased by approx. 9%. The wire diameter has also been increased by two ranks, so the resistance between terminals is reduced, and the insulation distance is shorter. This improves the motor’s operation performance and contributes to high- efficiency operation of the compressor.

Documentation

General Catalog

Comfort & IT Cooling Systems - Full product catalogue 2024

Download